Green sand casting

Green Sand Casting

About Green Sand Casting

Green sand casting is a traditional metal casting process using a mold made from moist sand. Green sand casting uses silica sand, clay, and water to create molds. It’s cost-effective, versatile, and widely applied for complex parts.

Green-sand (or greensand) casting is a widely used process for manufacturing metal parts. The green appearance of the sand is due to the presence of moisture, bentonite clay, and sea coal. Sea coal is powdered bituminous coal that coincidentally washes up on beaches and is “naturally” present in beach sand as the first casting medium. This cast-making process offers a poorer surface finish and lesser precision/repeatability than more modern processes using less volatile and fragile binders.

Benefits of Green Sand Casting

1. Fast Production Cycles

Green sand casting allows for quick mold preparation and metal pouring, making it ideal for producing parts in relatively short lead times. Unlike permanent mold or investment casting, green sand molds can be prepared and reused quickly, reducing downtime between batches. This efficiency makes it suitable for industries that require rapid prototyping or fast delivery of small to medium production runs.

2. Cost-Effective for Small to Medium Batches

Because green sand molds are inexpensive to make and can often be reused several times, this process is highly economical for small to medium production quantities. There’s no need for expensive permanent molds or complex tooling, which reduces initial investment costs. Labor and material costs are also optimized, making the process competitive for many industrial applications.

3. Suitable for Various Metals

Green sand casting is compatible with a wide range of metals, including:

Grey Iron: Excellent for general machinery parts due to its good machinability and vibration damping.

Ductile Iron: Offers high strength and toughness for heavy-duty components.

Carbon Steel: Suitable for parts requiring higher strength and wear resistance.

Alloy Steel: Ideal for components that demand specialized mechanical properties, such as impact or corrosion resistance.

The flexibility in metal choice allows manufacturers to tailor material properties to meet specific performance requirements of each application.

4. Eco-Friendly Process

Green sand casting is environmentally friendly, as the sand used in molds can be recycled and reused multiple times. This reduces waste and the need for new raw materials. Additionally, the process does not require complex chemical binders, making it safer for workers and reducing environmental impact.

5. Typical Metals

The most commonly used metals in green sand casting include:

Grey Iron: Cost-effective, strong, and vibration-absorbing.

Ductile Iron: Strong, tough, and suitable for high-stress applications.

Carbon Steel: Offers higher mechanical strength and wear resistance.

Alloy Steel: Provides enhanced properties like toughness, corrosion resistance, and heat resistance.

These metals cover most industrial applications, from automotive and machinery to pump housings and mining equipment.

Detailed Process Steps

1.Pattern Making

Patterns are made from wood, metal, or resin, replicating the exact shape of the final casting.

Cope (top half) and drag (bottom half) are used for easy assembly.

2.Sand Preparation & Molding

Green sand consists of silica sand, clay, and water mixed to the correct consistency.

Sand is packed around the pattern, providing support and shape for the mold.

3.Core Making

Cores form internal cavities or hollow sections in the casting.

Strong and heat-resistant cores allow complex internal designs.

4.Mold Assembly & Pouring

Mold halves are assembled with gates and risers to control metal flow.

Molten metal is poured into the mold, filling all cavities.

5.Cooling & Shakeout

The molten metal solidifies in the mold.

The sand mold is broken to extract the raw casting (shakeout).

6.Cleaning & Finishing

Remove sand residues, gates, risers, and burrs.

Shot blasting, grinding, and heat treatment improve surface quality and mechanical properties.

Applications of Green Sand Casting

1. Engine Blocks

Description: Engine blocks are critical components of automotive and industrial engines.

Performance Requirements: High mechanical strength, excellent heat resistance, vibration damping, and dimensional stability.

Typical Usage: Used in cars, trucks, heavy machinery, and generators. Green sand casting ensures precise internal cavities for coolant passages and oil channels while maintaining overall strength.

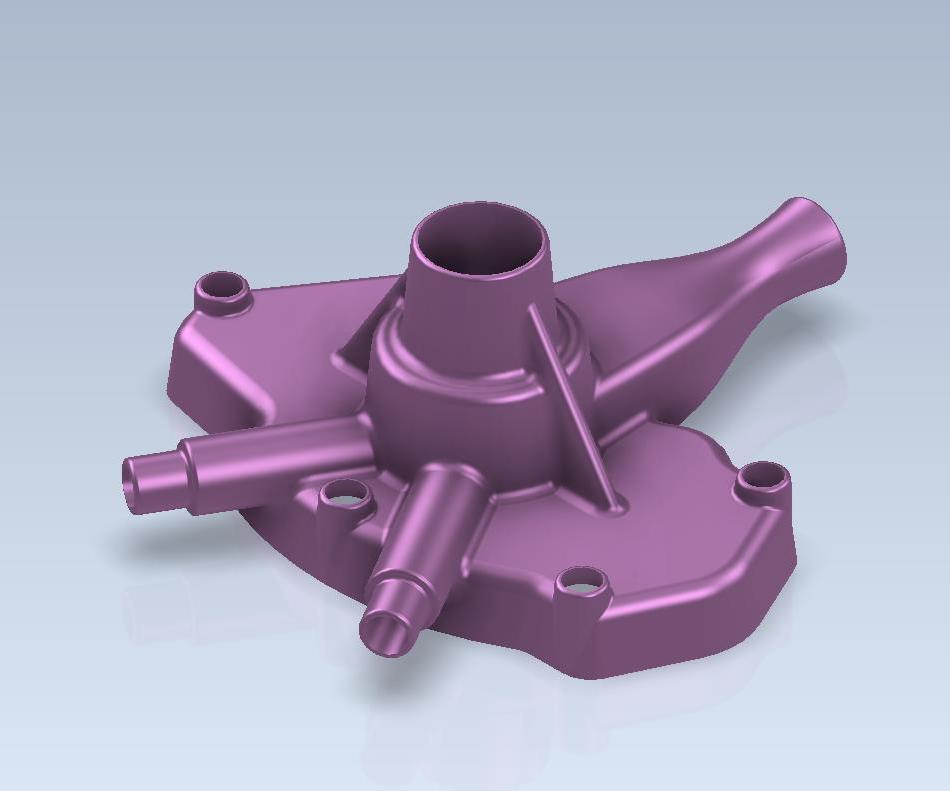

2. Pump Housings

Description: Pump housings are essential for fluid transfer systems, often exposed to corrosive or abrasive liquids.

Performance Requirements: Corrosion resistance, wear resistance, and structural integrity under high pressure.

Typical Usage: Water pumps, chemical pumps, slurry pumps, and industrial fluid handling systems. Green sand casting allows for complex shapes and reinforcement ribs to enhance durability.

3. Gearboxes

Description: Gearbox casings protect gears and bearings while transmitting power efficiently.

Performance Requirements: High dimensional accuracy, impact resistance, and precise alignment for smooth operation.

Typical Usage: Automotive transmissions, industrial machinery, agricultural equipment, and mining gear systems. Green sand casting produces tough and stable housings with precise tolerances.

4. Brake Drums

Description: Brake drums are critical components in automotive braking systems.

Performance Requirements: High wear resistance, thermal stability, and excellent heat dissipation to ensure safe braking performance.

Typical Usage: Cars, trucks, and commercial vehicles. Green sand casting allows consistent wall thickness and structural strength to withstand repeated braking cycles.

5. Custom Industrial Components

Description: Many industries require specialized castings for machinery and equipment.

Performance Requirements: Vary depending on application, but generally require toughness, wear resistance, and dimensional accuracy.

Typical Usage: Agricultural machinery, mining equipment, construction machinery, conveyor parts, pump casings, and heavy-duty industrial components. Green sand casting provides flexibility to produce complex shapes and large-size components economically

Examples of Sand Casting Products

FAQs

Q: Can green sand casting produce complex shapes?

A: Yes, with proper cores and gating systems, intricate designs are achievable.

Q: How fast is the production cycle?

A: Typically 45–55 days depending on casting size and complexity.

Q: Can sand be reused?

A: Yes, green sand is recyclable, making the process eco-friendly.

Q: Which metals can be cast?

A: Commonly used for grey iron, ductile iron, carbon steel, and alloy steel.

Q: What size range is possible?

A: From small parts under 1 kg to very large castings over several tons.

Q: Which industries use it?

A: Automotive, agriculture, mining, construction machinery, and general industrial equipment.

Q: Can it produce custom parts?

A: Yes, green sand molds can be shaped for a wide range of custom designs.