Alloy Steel casting

Alloy Steel Casting

Alloy steel casting refers to cast components made from steel that contains significant amounts of alloying elements such as chromium, nickel, molybdenum, vanadium, or manganese. These alloying elements are added to improve mechanical properties, wear resistance, corrosion resistance, and heat resistance compared to carbon steel castings.

Due to their enhanced strength, toughness, and ability to perform under extreme conditions, alloy steel castings are widely used in industries such as mining, construction machinery, oil & gas, power generation, shipbuilding, and heavy equipment manufacturing. Common applications include gears, valve bodies, pump housings, turbine components, and crusher parts.

Alloy steel castings are typically produced using processes like sand casting, investment casting, and centrifugal casting, followed by heat treatment to achieve the desired hardness and microstructure. The combination of precise casting technology and controlled alloy composition ensures high dimensional accuracy, structural integrity, and long service life.

We specialize in producing high-quality alloy steel castings for demanding industries worldwide. With advanced foundry facilities, CNC machining workshops, and strict quality assurance, we provide strong, wear-resistant, and heat-resistant components designed for heavy-duty applications. Our alloy steel castings combine superior mechanical properties with cost-effective production, making them the preferred choice for mining, construction, power generation, and machinery manufacturing.

Key Characteristics:

High Strength & Toughness – Maintains excellent load-bearing capacity and impact resistance.

Wear & Abrasion Resistance – Ideal for parts subject to friction and heavy wear.

Corrosion & Oxidation Resistance – Performs well in harsh or corrosive environments.

High Temperature Performance – Retains mechanical properties under elevated temperatures.

Customizable Alloy Composition – Alloying elements can be adjusted to meet specific application needs.

Dimensional Accuracy – Achieved through precise casting processes and quality control.

Extended Service Life – Durable performance reduces maintenance and replacement costs.

Product Range

Content:

Couplings & Housings – High load capacity and dimensional accuracy.

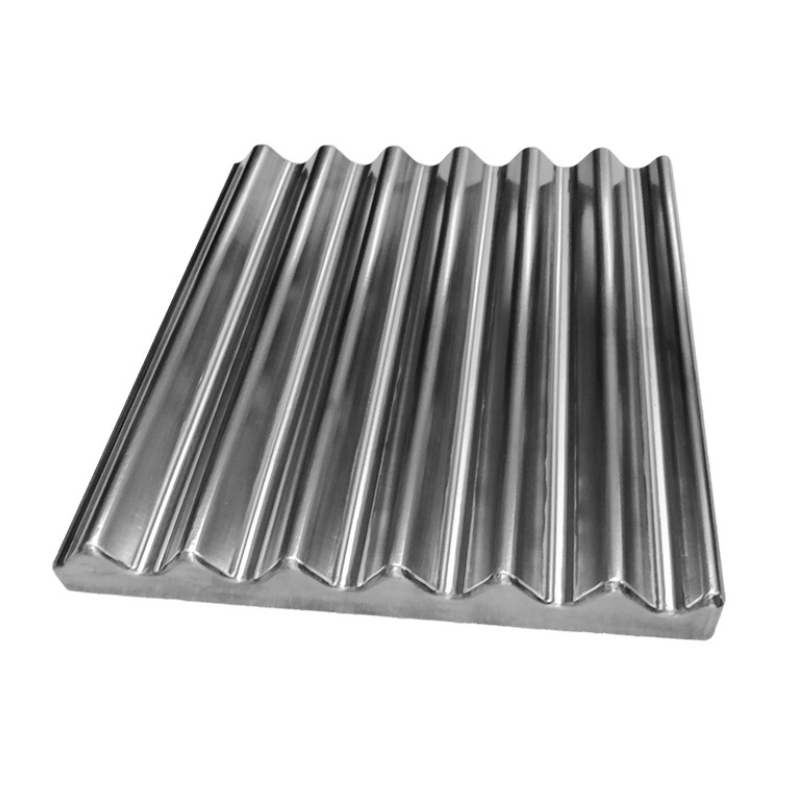

Crusher Plates & Liners – Wear-resistant parts for mining and crushing industries.

Excavator Track Shoes – Strong and impact-resistant for construction machinery.

Bearing Seats & Gear Wheels – High fatigue strength and reliable transmission.

Jaw Crusher Components – Heat-treated castings for longer service life.

Link Rods & Connecting Rods – High-strength structural components.

Customized Alloy Steel Parts – Manufactured according to customer designs and specifications.

Case Studies

Mechanical character

Technical Specifications

Content:

Grades: ZG310-570, ZG20CrMo, ZG35CrNiMo, AISI 4140, AISI 4340

Tensile Strength: 600–1000 MPa

Hardness (HB): 160–320 (depending on grade and treatment)

Impact Strength: Excellent toughness for heavy-duty conditions

Wear Resistance: Significantly higher than carbon steel castings

Heat Resistance: Stable mechanical properties at elevated temperatures

| Grade (ASTM / AISI / GB) | Alloying Elements | Tensile Strength (MPa) | Hardness (HB) | Key Characteristics | Typical Applications |

|---|---|---|---|---|---|

| ZG310-570 (GB) | Mn, Si | 570–700 | 160–200 | General-purpose alloy steel casting with good strength and machinability | Machinery housings, brackets |

| ZG20CrMo (GB) | Cr, Mo | 600–800 | 170–220 | High toughness, good wear resistance, excellent hardenability | Shafts, gears, transmission parts |

| ZG35CrNiMo (GB) | Cr, Ni, Mo | 700–950 | 200–260 | High strength, fatigue resistance, impact toughness | Bearings, heavy-duty machinery parts |

| AISI 4140 (42CrMo) | Cr, Mo | 655–950 | 200–260 | Excellent strength-to-toughness ratio, good fatigue resistance | Gears, connecting rods, crankshafts |

| AISI 4340 (40CrNiMoA) | Ni, Cr, Mo | 850–1000+ | 240–320 | Ultra-high strength, excellent toughness, wear and shock resistance | Aerospace, heavy equipment, shafts |

| ZG40Mn (GB) | Mn | 600–750 | 170–220 | High wear resistance, cost-effective | Crusher hammers, wear plates |

| ZG30SiMn (GB) | Si, Mn | 600–800 | 170–230 | High impact strength, good toughness | Mining machinery, gears |

Comprehensive Services & Capabilities

Content:

Design Support – Assistance with drawings, modeling, and casting feasibility analysis.

Custom Tooling – In-house pattern and mold design to meet unique project requirements.

Flexible Production – Capable of handling both complex single parts and large batch orders.

Surface Treatments – Shot blasting, painting, galvanizing, and anti-rust coatings.

Assembly & Finishing – Machined castings with optional sub-assembly services.

Documentation & Certification – Material certificates, inspection reports, and compliance with international standards.

Global Partnerships – Long-term cooperation with clients in automotive, machinery, energy, and construction industries.

Quality Assurance

Content:

ISO 9001 certified production and management system.

100% chemical composition testing using spectrometer.

Mechanical property testing for every heat treatment batch.

Dimensional inspection with CMM.

Support for third-party inspection (SGS, BV, TÜV).

Applications

Content:

Mining Industry – Crusher liners, wear plates, and hammers.

Construction Machinery – Excavator parts, track shoes, and couplings.

Power Generation – Turbine housings and heat-resistant components.

Oil & Gas – Pressure-resistant housings, valve bodies.

Heavy Equipment – Transmission gears, shafts, and connecting rods.