CNC machining

CNC Machining

1. About CNC Machining

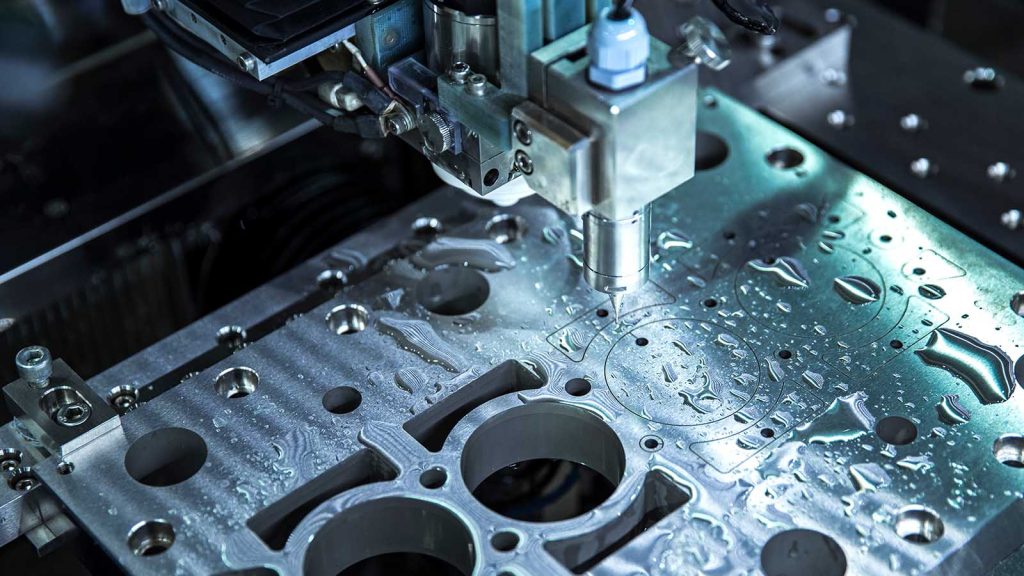

CNC (Computer Numerical Control) machining is a precision subtractive manufacturing process that uses computer-controlled machine tools to remove material from a solid workpiece. The process begins with a digital CAD model, which is converted into a set of machine-readable instructions (G-code). These instructions guide cutting tools such as mills, lathes, drills, or grinders to shape the raw material into the final component.

Unlike manual machining, CNC machining is automated, highly accurate, and repeatable, making it an essential technology for industries that demand consistency and tight tolerances.

2. Key Advantages

High Precision & Accuracy – Achieves tight tolerances down to microns, ideal for complex designs.

Excellent Surface Finish – Provides smooth finishes, often eliminating the need for further polishing.

Material Flexibility – Compatible with metals (steel, aluminum, titanium, copper), plastics, and composites.

Repeatability & Consistency – Ensures identical parts across small or large production runs.

Rapid Prototyping & Production – Speeds up product development and reduces lead times.

Complex Geometry – Capable of producing 2D, 3D, and multi-axis complex components.

3. Process Steps

Step 1: CAD Design

A 3D CAD model of the part is created with precise dimensions.

Step 2: CAM Programming

The CAD file is converted into CAM instructions, generating toolpaths for the CNC machine.

Step 3: Machine Setup

The workpiece material is clamped, and cutting tools are installed in the CNC machine.

Step 4: Machining Operation

The CNC machine executes programmed toolpaths to cut, mill, drill, or turn the material into the final shape.

Step 5: Finishing & Inspection

Post-processing such as deburring, polishing, heat treatment, or coating is applied, followed by quality inspection.

Machining sample examples

Casting vs CNC Machining

| Aspect | Casting | CNC Machining |

|---|---|---|

| Best For | Large, complex shapes; bulk production | High-precision, complex details; prototypes and small to medium batches |

| Material Use | Wide range of metals and alloys | Metals, plastics, composites |

| Precision & Tolerance | Moderate (depends on casting method) | Very high (±0.01 mm) |

| Surface Finish | Rougher, often needs machining | Excellent finish, often ready-to-use |

| Production Speed | Fast for large volumes | Fast for prototypes, slower for high-volume |

| Cost Efficiency | Low cost per part in mass production | Higher cost per part, economical for precision parts |

| Design Flexibility | Great for large, hollow, or complex shapes | Best for precise geometries and fine details |

| Typical Industries | Automotive, heavy machinery, energy | Aerospace, medical, electronics, automotive precision parts |

FAQs

Q: What materials can be CNC machined?

A: Metals (steel, stainless steel, aluminum, titanium, copper), plastics, and composites.

Q: What tolerances can CNC machining achieve?

A: Typically ±0.01 mm, depending on material and machine setup.

Q: What is the difference between CNC milling and CNC turning?

A: Milling uses rotating cutting tools, while turning rotates the workpiece against a stationary tool.

Q: Is CNC machining suitable for mass production?

A: Yes, especially when combined with automation, but it is also efficient for small batches and prototypes.

Q: How does CNC machining compare with casting?

A: CNC machining offers higher precision and better surface finishes, while casting is more cost-effective for very large or complex parts.