Grey iron casting

Grey Iron Casting

Grey iron casting is a widely used metalworking process in which molten grey iron is poured into a mold to create components with specific shapes and properties. Grey iron, named for its characteristic gray-colored fracture surface, owes its appearance to the presence of flake graphite in its microstructure. This graphite provides unique benefits, such as excellent thermal conductivity, vibration damping, and machinability, making grey iron an ideal material for various industrial applications.

We specialize in the production of gray iron castings, delivering high-quality components for industries such as machinery manufacturing, automotive parts, pumps, and valves. With years of expertise and a fully integrated production line, we provide complete solutions from casting to finished components, ensuring reliability and consistency for our global clients.

Key Characteristics:

Excellent Vibration Damping – Suitable for heavy-duty machinery and machine tools.

High Machinability – Graphite flakes provide smooth cutting and extended tool life.

Cost-Effective – Combines performance with production efficiency.

Stable Dimensions – Minimal deformation after solidification, ideal for precision parts.

Wear Resistance – Perfect for friction-intensive components like brake drums and guides.

Product Range

Content:

Pump Bodies & Covers – Designed for water and chemical pumps with excellent wear resistance.

Valve Bodies – Reliable sealing and high pressure resistance for fluid control systems.

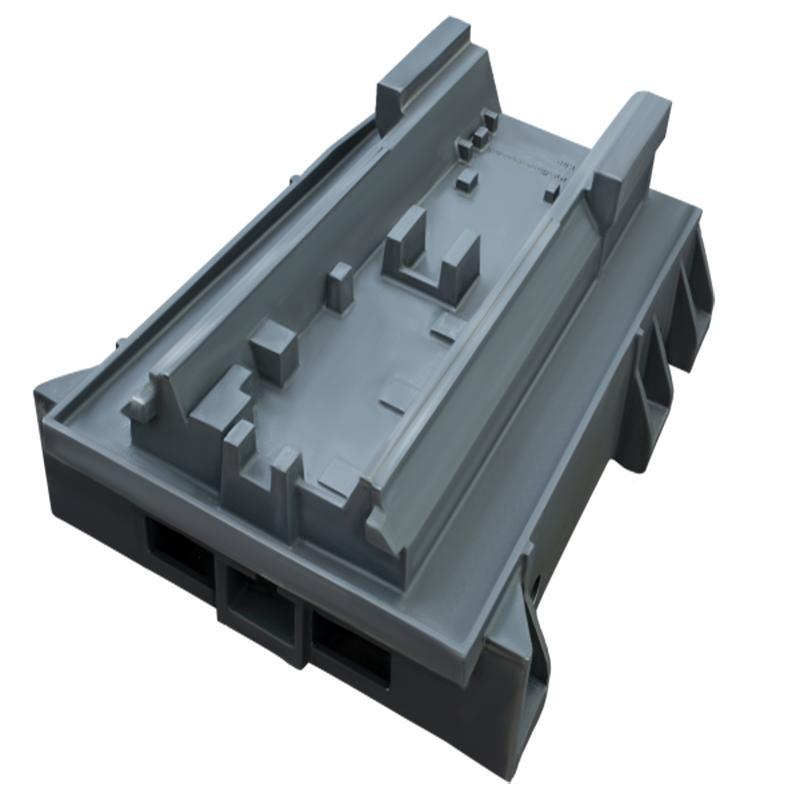

Machine Tool Beds – Superior vibration damping for stable machining performance.

Gearbox Housings – Strong and dimensionally accurate for transmission systems.

Automotive Brake Drums & Components – Excellent heat resistance and durability for safe braking.

General Structural Parts – Brackets, bases, housings, customized to customer drawings.

Case Studies

Mechanical character

Technical Specifications

Content:

Grades: EN-GJL-200, EN-GJL-250, EN-GJL-300

Tensile Strength: 200–300 MPa

Compressive Strength: 600–1200 MPa

Hardness (HB): 150–230

Thermal Conductivity: 46–54 W/m·K

Dimensional Tolerance: ISO/GB standards or as per customer request

Gray Iron Material Grades | ||||||||

Country | Standard | Equivalent Grades of Grey Iron (Gray Cast Iron) | ||||||

ISO | ISO 185 | 100 | 150 | 200 | 250 | 300 | 350 | – |

China | GB 9439 | HT100 | HT150 | HT200 | HT250 | HT300 | HT350 | – |

USA | ASTM A48 | – | NO.20 | NO.30 | NO.35 | NO.40 | NO.50 | NO.55 |

NO.25 | NO.45 | NO.60 | ||||||

Germany | DIN 1691 | GG10 | GG15 | GG25 | GG30 | |||

Austria | ||||||||

European | EN 1561 | EN-GJL-100 | EN-GJL-150 | EN-GJL-200 | EN-GJL-350 | |||

Japan | JIS G5501 | FC100 | FC200 | FC250 | FC300 | FC350 | – | |

Italy | UNI 5007 | G10 | G15 | G20 | G25 | G30 | G35 | – |

France | NF A32-101 | – | FGL150 | FGL200 | FGL250 | FGL300 | FGL350 | FGL400 |

UK | BS 1452 | 100 | 150 | 200 | 250 | 300 | 350 | – |

India | IS 210 | – | FG150 | FG200 | FG260 | FG300 | FG350 | FG400 |

Spain | UNF | – | FG15 | FG20 | FG25 | FG30 | FG35 | – |

Belgium | NBN 830-01 | FGG10 | FGG15 | FGG20 | FGG25 | FGG30 | FGG35 | FGG40 |

Australia | AS 1830 | – | T150 | T220 | T260 | T300 | T350 | T400 |

Sweden | SS 14 01 | O110 | O115 | O120 | O125 | O130 | O135 | O140 |

Norway | NS11 100 | SJG100 | SJG150 | SJG200 | SJG250 | SJG300 | SJG350 | – |

Capabilities & Facilities

Foundry Capacity

Equipped with medium-frequency induction furnaces, ensuring precise melting and stable composition control.

Molding Solutions

Ability to produce both small and large castings using green sand, resin sand, and shell molding technologies.

Machining Facilities

CNC machining centers, lathes, and milling machines guarantee tight tolerance and high surface quality.

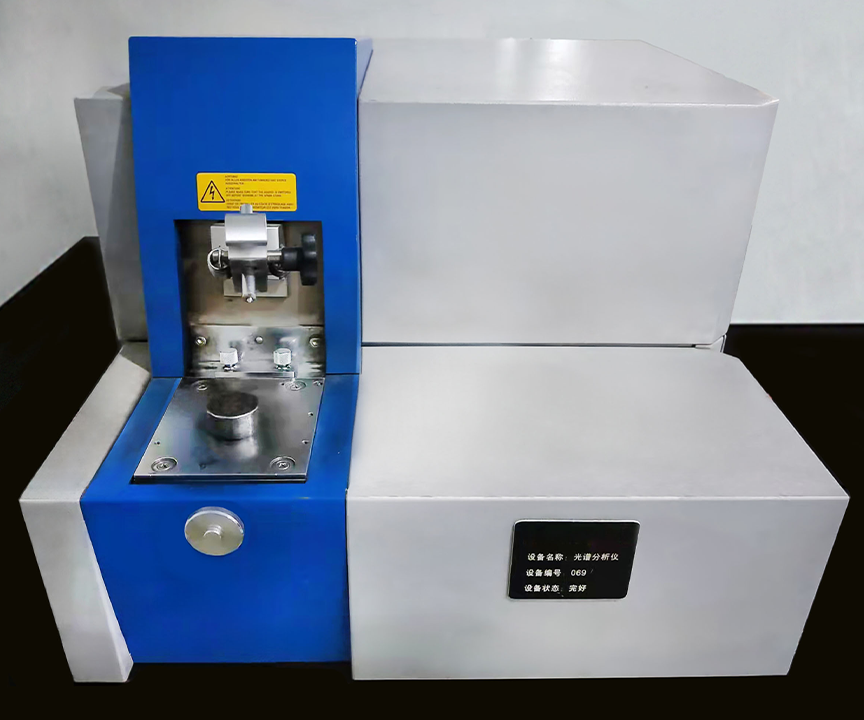

Testing Equipment

Spectrometers, hardness testers, coordinate measuring machines (CMM), and non-destructive testing (NDT) instruments.

Production Scale

Annual capacity of thousands of tons, with flexible batch sizes from prototypes to mass production.

Logistics Support

Professional packaging and international shipping solutions tailored to customer needs.

Quality Assurance

Content:

ISO 9001 certified production system.

Every batch includes full chemical and mechanical property reports.

Support for third-party inspection (SGS, BV, etc.).

Batch traceability and strict internal quality audits.

Applications

Content:

Construction Machinery – Frames, housings, brackets.

Automotive Industry – Brake systems, engine-related castings.

Agricultural Equipment – Housings and transmission parts.

Pumps & Valves – Critical flow control components.

Machine Tools – Beds and structures requiring vibration damping.