Investment casting

About Investment Casting

What It Is

Investment casting, also known as lost-wax casting, is a precision casting process used to manufacture complex metal components with high accuracy and excellent surface finish. The process begins with creating a wax pattern that is an exact replica of the desired part. The wax pattern is repeatedly coated with refractory ceramic material to form a strong shell. After the wax is melted out, molten metal is poured into the cavity, producing a highly accurate casting that closely matches the original design.

This method is particularly valued when parts require tight tolerances, smooth surfaces, and complex geometries that are difficult or impossible to achieve through other casting techniques.

Advantages

High Detail and Thin Walls

Investment casting can reproduce intricate features such as sharp corners, logos, lettering, and internal passages.

It allows for the creation of thin-walled sections (as low as 1.5–2.5 mm), reducing weight while maintaining strength.

Excellent Surface Finish

The ceramic mold surface provides a smooth casting finish (Ra 1.6–3.2 μm).

This minimizes or even eliminates the need for post-casting machining, saving time and cost.

Complex Geometries

Capable of producing parts with undercuts, internal cavities, intricate curves, and lattice structures.

Reduces the need for welding or assembly of multiple components, simplifying production.

Wide Material Compatibility

Suitable for ferrous and non-ferrous metals, including:

Steel and Stainless Steel: High strength and corrosion resistance.

Superalloys: Excellent for high-temperature applications (e.g., turbine blades).

Aluminum Alloys: Lightweight, good for automotive and aerospace parts.

Copper Alloys: Good conductivity and wear resistance.

This versatility allows the process to meet diverse mechanical and environmental requirements.

Reduced Material Waste

Produces near-net-shape components, meaning the part requires little additional machining.

Efficient use of materials lowers cost and reduces environmental impact.

Detailed Process Steps

1.Wax Pattern Creation

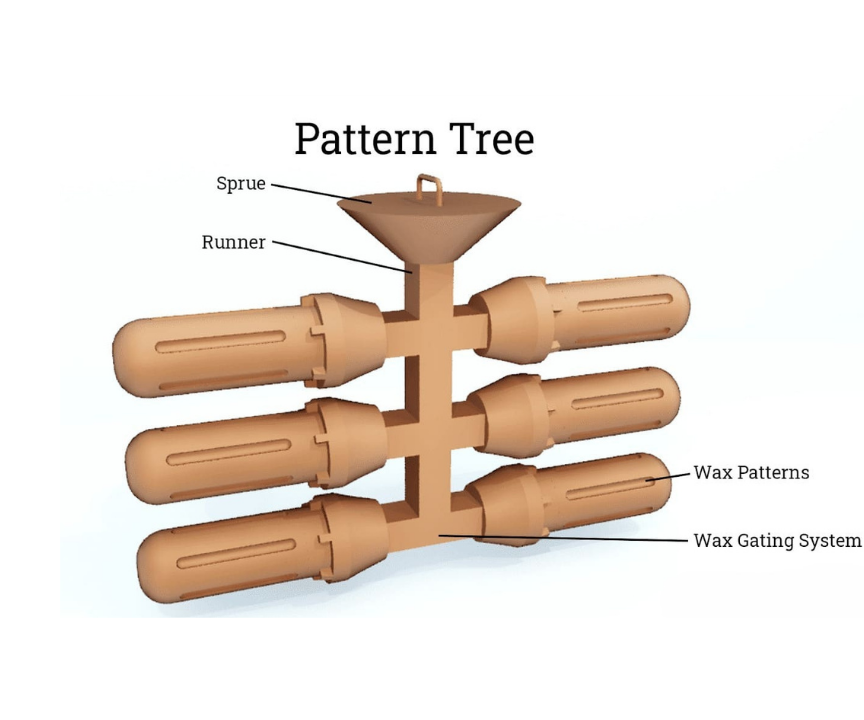

The process begins with the production of wax patterns, which are exact replicas of the final component. These patterns are created by injecting molten wax into precision-designed metal molds. For higher productivity, multiple wax patterns are assembled onto a central wax runner system, forming a “pattern tree” that allows several parts to be cast in a single batch.

2.Shell Building

The wax pattern tree is repeatedly dipped into a ceramic slurry and then coated with fine refractory sand. After each coating, it is dried and hardened before the next layer is applied. This sequence is repeated multiple times until a strong, multilayered ceramic shell is formed, typically 5–10 mm thick. The shell must be durable enough to withstand both the dewaxing process and the high temperatures of molten metal.

3.Dewaxing

Once the ceramic shell is fully built, the entire assembly is placed in an autoclave or furnace. The wax inside melts and drains out, leaving behind a hollow ceramic mold. This step is critical because it ensures the internal cavity precisely matches the original wax pattern, capturing every fine detail of the design.

4.Shell Firing

The hollow ceramic shell is then fired at high temperature. Firing serves two purposes: it removes any remaining wax residue and strengthens the ceramic shell to withstand the extreme heat and pressure of molten metal pouring. Preheating the mold also helps improve metal flow and reduces the risk of defects.

5.Metal Pouring & Solidification

Molten metal is poured into the preheated ceramic mold under gravity or vacuum-assisted techniques. The liquid metal fills every intricate cavity of the shell, reproducing fine details and thin walls with high accuracy. After pouring, the metal is left to cool and solidify within the ceramic mold.

6.Shell Removal & Finishing

Once the metal has solidified, the ceramic shell is broken away, exposing the cast components. The individual parts are cut off from the central runner system. Depending on requirements, the castings undergo further finishing operations, including grinding, heat treatment, surface polishing, or precision machining, to achieve the final specifications.

Applications of Investment Casting

1. Aerospace Industry

Use Cases: Turbine blades, engine brackets, structural components, and fuel system parts.

Why Investment Casting: Provides excellent dimensional accuracy and surface finish for parts exposed to extreme heat, stress, and vibration. Enables lightweight, high-strength designs that improve aircraft efficiency.

2. Automotive Industry

Use Cases: Turbocharger wheels, rocker arms, gears, and brake components.

Why Investment Casting: Produces complex shapes and thin-walled sections that reduce vehicle weight while maintaining durability. Improves fuel efficiency and performance in engines and transmissions.

3. Medical Industry

Use Cases: Orthopedic implants (hip and knee joints), dental implants, and surgical instruments.

Why Investment Casting: Allows the production of biocompatible components with smooth surfaces and intricate geometries. Ensures precision and safety in medical applications.

4. Energy & Power Generation

Use Cases: Gas turbine parts, pump impellers, valve bodies, and components for oil & gas systems.

Why Investment Casting: Delivers high-strength, heat-resistant parts that withstand harsh environments. Essential for reliable operation of power plants, oil rigs, and chemical processing systems.

5. Industrial Machinery & Equipment

Use Cases: Mining machinery parts, agricultural machinery components, and custom machine tools.

Why Investment Casting: Provides flexibility in design, producing wear-resistant and heavy-duty parts economically. Reduces the need for welding or assembly of multiple components.

Examples of Investment Casting Products

FAQs

Q: What is investment casting?

A: A precision casting process (lost-wax method) for producing complex, accurate metal parts with smooth surfaces.

Q: Which metals can be cast?

A: Steel, stainless steel, superalloys, aluminum, copper alloys, and more.

Q: What are the main benefits?

A: High accuracy, smooth surface finish, ability to cast complex shapes, wide material compatibility, less machining.

Q:What size range is possible?

A: From a few grams up to ~50 kg depending on design and alloy.

Q: Which industries use it?

A: Aerospace, automotive, medical, energy, and industrial machinery.

Q: How does it compare to sand or die casting?

A: More precise and versatile than sand casting, works with more alloys than die casting, but longer lead times.

Q: Can it be customized?

A: Yes, investment casting is ideal for custom, complex, or unique part designs.