Lost foam casting

About Lost Foam Casting

What It Is

Lost foam casting is an innovative precision casting process that uses expendable foam patterns, typically made from polystyrene, to create highly accurate metal castings. The foam pattern is first coated with a thin refractory layer, which improves mold strength and surface quality. The coated pattern is then embedded in unbonded dry sand that is compacted through vibration.

When molten metal is poured into the mold, the foam pattern vaporizes instantly and is replaced by the metal, forming a casting that faithfully replicates the original foam shape. This process eliminates the need for traditional cores and mold parting lines, making it ideal for producing complex geometries in a single step.

Advantages

Complex Shapes in One Step

Capable of producing intricate designs, internal cavities, and thin-walled sections without the use of cores.

Reduces the need for welding or assembling multiple parts, simplifying production.

No Need for Cores

Traditional sand casting often requires separate cores for hollow sections, but lost foam casting eliminates this step.

Improves efficiency, reduces errors, and lowers machining costs.

High Dimensional Accuracy and Surface Finish

Provides smooth surfaces (Ra 3.2–6.3 μm) and tight tolerances.

Minimizes post-casting machining, saving time and cost.

Cost-Effective for Medium to Large Production

Foam patterns can be produced quickly and inexpensively, especially for batch or mass production.

Sand is reusable, and the process reduces tooling complexity compared to other precision casting methods.

Material Flexibility

Suitable for a wide range of ferrous and non-ferrous metals, including grey iron, ductile iron, carbon steel, alloy steel, and aluminum alloys.

Enables production of castings that meet diverse strength, weight, and corrosion-resistance requirements.

1.Foam Pattern Production

Polystyrene foam is used to create the exact shape of the desired part. Patterns can be cut by machining or formed through molding, ensuring dimensional accuracy. For efficiency, multiple foam patterns may be assembled into a cluster or "tree."

2.Pattern Assembly & Preparation

Single patterns or clusters are mounted onto a gating system. This assembly prepares the foam for the coating process and ensures smooth metal flow during casting.

3.Refractory Coating Application

The foam pattern is dipped or sprayed with a thin refractory coating. This layer strengthens the pattern surface, improves mold permeability, and enhances the final casting’s accuracy and finish.

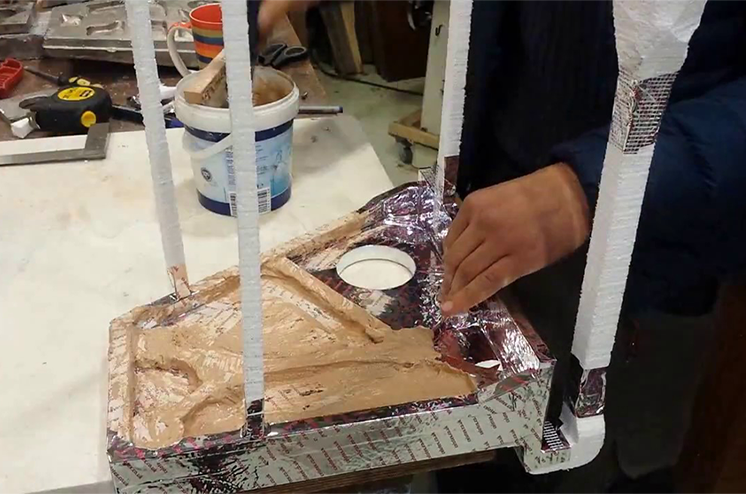

4.Mold Box Filling & Sand Compaction

The coated foam pattern is placed inside a flask (molding box) and surrounded by unbonded dry sand. Vibration is applied to compact the sand tightly around the foam, providing support during metal pouring.

5.Metal Pouring & Foam Evaporation

Molten metal is poured directly into the sand mold. The heat causes the foam pattern to vaporize instantly, allowing the liquid metal to fill the cavity and replicate the original design with high precision.

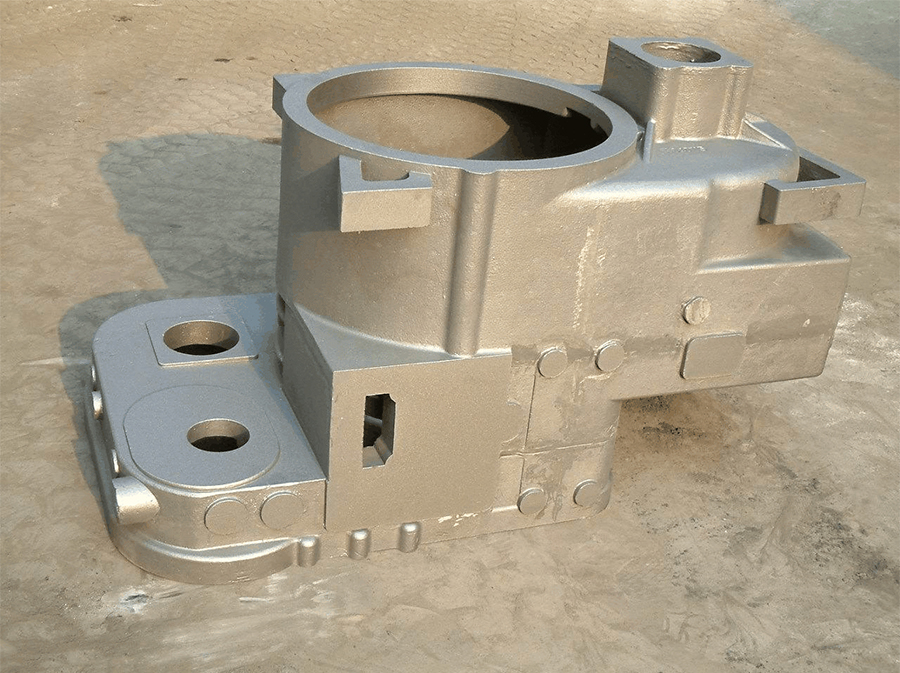

6.Cooling, Shakeout & Finishing

Once the metal solidifies, the surrounding sand is removed and recycled. The casting is separated from the gating system, cleaned, and subjected to finishing processes such as grinding, machining, or heat treatment to achieve the required specifications.

Applications of Lost Foam Casting

1. Automotive Industry

Examples: Engine blocks, cylinder heads, intake manifolds, brake components.

Why Lost Foam Casting: This process eliminates the need for complex cores, making it ideal for producing hollow and intricate shapes such as coolant passages inside engine blocks. It provides excellent dimensional stability, good surface finish, and reduces post-machining, which is critical for modern automotive lightweight and fuel-efficient designs.

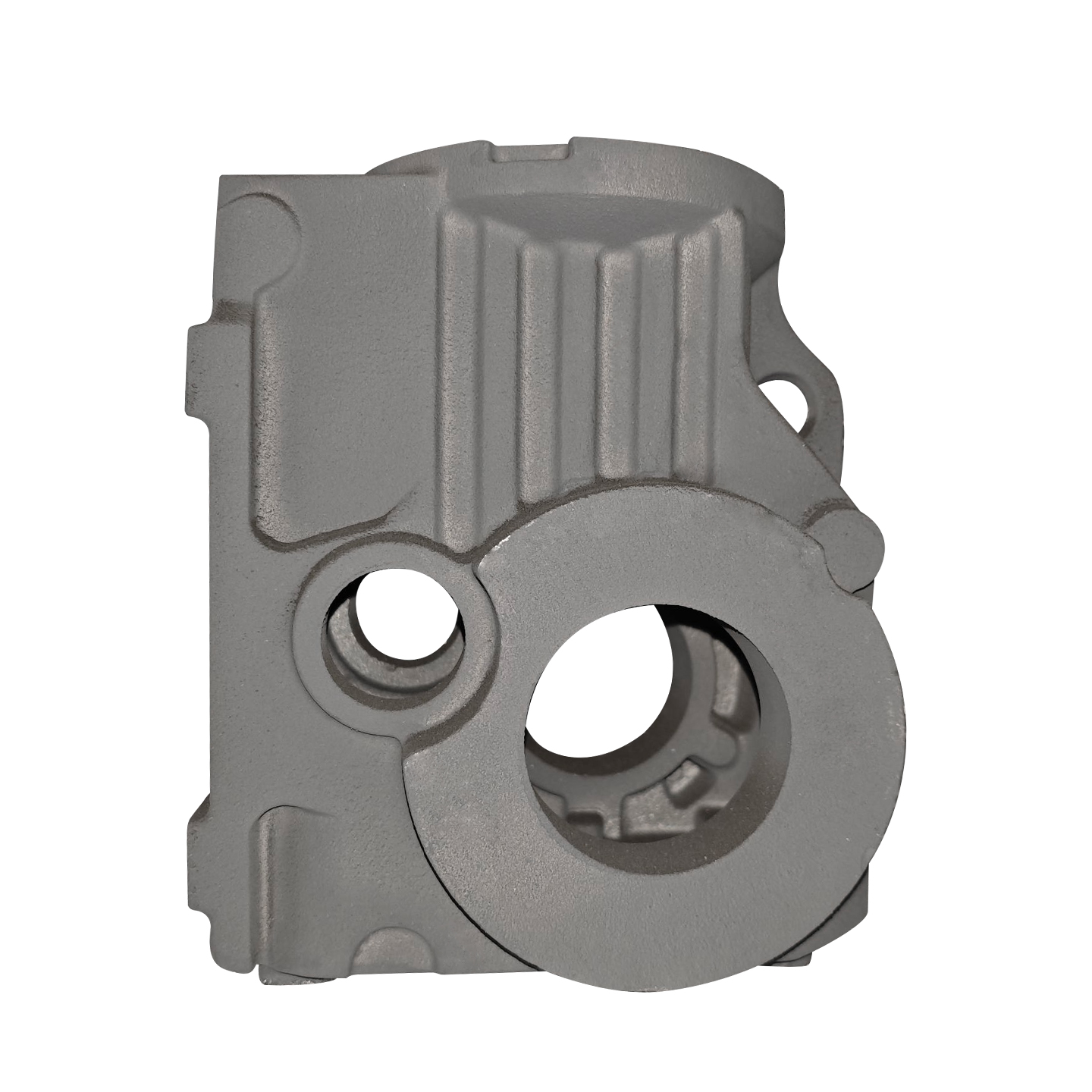

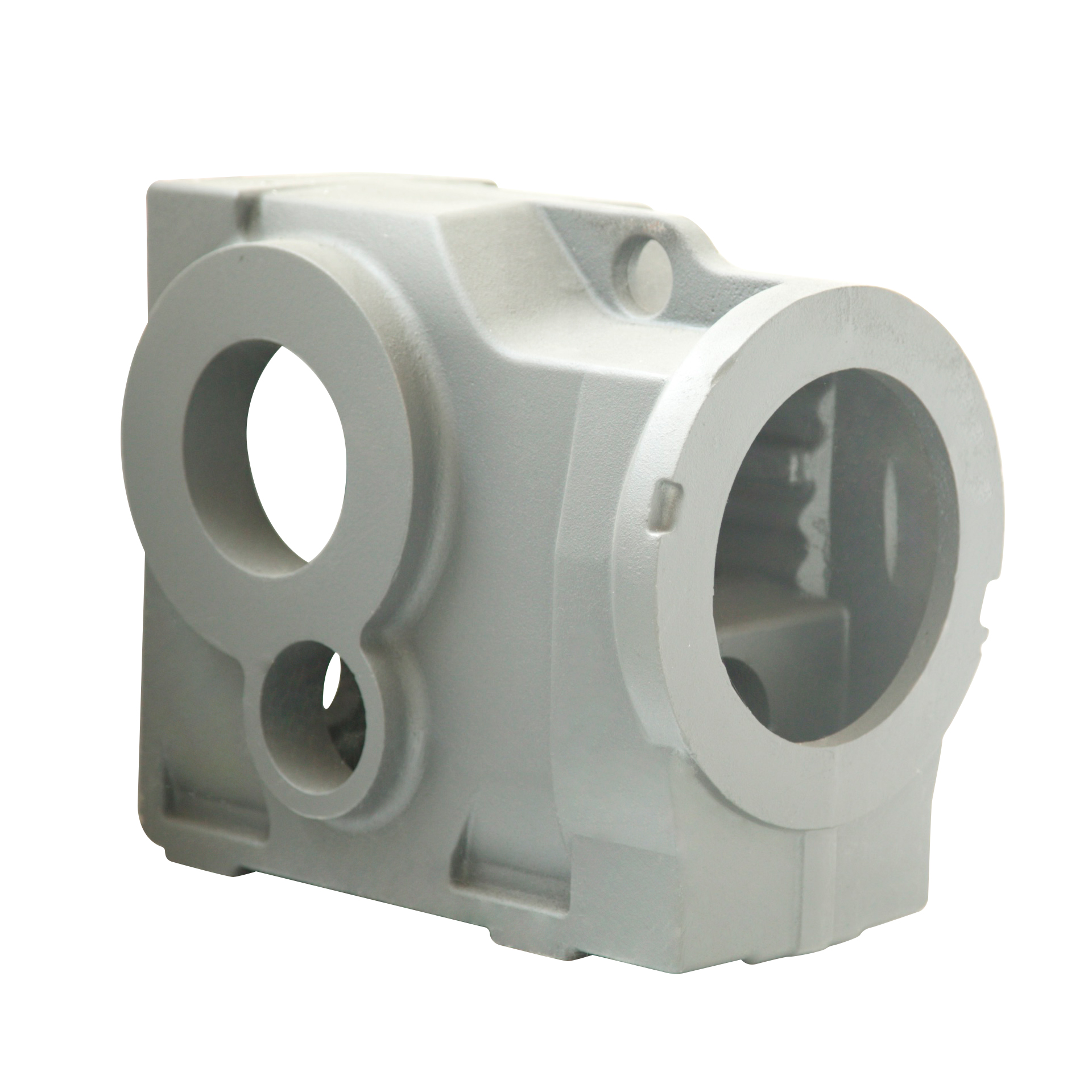

2. Heavy Machinery

Examples: Pump housings, gearboxes, machine tool frames, and structural components.

Why Lost Foam Casting: Heavy machinery requires large and durable castings with high structural integrity. Lost foam casting allows these parts to be cast as a single piece, avoiding multiple assemblies and welding. This results in higher strength, reduced weak points, and lower overall manufacturing costs.

3. Energy Industry

Examples: Turbine casings, valve bodies, pipe fittings, and impellers.

Why Lost Foam Casting: Energy applications demand parts that can handle high pressure, high temperature, and corrosive environments. Lost foam casting ensures complex internal designs and smooth flow paths for fluid handling components, improving performance and service life in power plants, oil & gas, and chemical processing systems.

4. Agricultural & Mining Equipment

Examples: Wear-resistant components, shovel arms, brackets, large structural castings.

Why Lost Foam Casting: Agriculture and mining equipment often require large, heavy-duty parts with high wear resistance. Lost foam casting provides cost-effective production of oversized and complex geometries, making it possible to replace multiple welded components with a single robust casting.

5. General Industrial Parts

Examples: Custom housings, machine brackets, conveyor components, and specialized fittings.

Why Lost Foam Casting: This process offers flexibility for producing both standard and custom designs with intricate features. It is particularly useful for industrial parts where design complexity, accuracy, and durability are required, while keeping production economical.

Examples of Lost Foam Casting Products

FAQs

Q: What materials are used in lost foam casting?

A: Grey iron, ductile iron, carbon steel, aluminum, and other alloys.

Q: What are the main benefits?

A: Complex shapes without cores, reduced machining, and cost-effective for large parts.

Q: How does it compare with green sand casting?

A: Lost foam casting allows more complex designs and eliminates cores, while green sand casting is faster and cheaper for simple parts.

Q: What is the size range of lost foam castings?

A: It can produce both small precision components and very large structural castings weighing several tons.

Q: Is the sand used in lost foam casting reusable?

A: Yes, unbonded sand is used and can be recycled multiple times, making the process eco-friendly.

Q: What industries benefit most from lost foam casting?

A: Automotive, energy, machinery, agricultural equipment, mining, and heavy equipment manufacturing.

Q: What surface finish can be expected?

A: Typically Ra 3.2–6.3 μm, which reduces or eliminates the need for extensive machining.