No bake resin sand casting

About No-Bake Resin Sand Casting

No-bake resin sand casting, also known as self-hardening sand casting, is a modern molding technique that uses a blend of high-quality silica sand and liquid resin binders. Once the sand and resin are mixed with a hardener, the mixture cures at room temperature, eliminating the need for external heating or baking.

This process produces molds with superior strength and stability, capable of handling large, heavy, and complex castings that traditional green sand methods cannot easily achieve. Because the resin-coated sand forms a rigid mold, it ensures excellent dimensional accuracy and surface smoothness, which reduces or even eliminates the need for extensive post-machining.

No-bake resin sand casting is widely adopted in industries that require precision, durability, and flexibility in production. It is particularly suitable for producing ferrous alloys (such as grey iron, ductile iron, carbon steel, and alloy steel) as well as non-ferrous metals like aluminum and copper alloys.

Key Advantages

High Dimensional Accuracy

The self-hardening nature of the resin binder creates molds that retain their shape with minimal distortion. This ensures the production of parts with tight tolerances and complex geometries, making it ideal for engineering components that demand precision.Strong Mold Strength

Unlike green sand molds, no-bake resin sand molds are rigid and durable, allowing them to withstand the high pressure and thermal stresses of pouring molten metal. This makes the process especially effective for very large castings, sometimes weighing several tons.Excellent Surface Finish

The smooth mold cavity surface leads to castings with a superior finish, typically requiring less grinding, machining, or polishing afterward. This not only saves time and cost but also improves the overall efficiency of the production process.Versatile Applications

The process is compatible with a wide variety of metals, including ferrous (steel, alloy steel, grey iron, ductile iron) and non-ferrous alloys (aluminum, bronze, brass). This versatility makes it suitable for producing components for industries ranging from automotive to energy.Flexible Production

No-bake resin sand casting is well-suited for small batch production, prototypes, and customized large parts. Manufacturers can produce both one-off specialized components and medium-volume runs without investing in expensive permanent tooling, offering flexibility and cost-effectiveness.

1.Pattern Preparation

Patterns are created based on the exact dimensions and geometry of the desired casting. They can be made of wood, plastic, or metal depending on production needs. To improve durability and ensure smooth release, the pattern surface is often treated with coatings or sealants. High-precision patterns are especially important for complex or large-scale castings.

2.Sand & Resin Mixing

High-quality silica sand is blended with a liquid resin binder and a chemical hardener. The proportions are carefully controlled to achieve the right balance between flowability, strength, and curing speed. This self-hardening mixture eliminates the need for baking, as the chemical reaction causes the sand to cure and harden at room temperature.

3.Mold Formation

The resin-coated sand is packed around the pattern inside a molding box. Vibration or manual compaction ensures that the sand fully surrounds the pattern and eliminates air gaps. As the mixture cures, it forms a rigid, dimensionally stable mold capable of holding the molten metal without deformation.

4.Mold Assembly

Once the mold halves are ready, they are carefully aligned and joined together. If the casting design requires hollow sections or internal cavities, cores made from the same resin sand process are inserted before assembly. Proper alignment is critical to achieving accuracy and minimizing defects.

5.Metal Pouring

Molten metal—such as grey iron, ductile iron, carbon steel, alloy steel, or non-ferrous alloys—is poured into the mold cavity. The high strength of the resin sand mold ensures it can withstand thermal stresses during pouring, even for large or heavy castings. The metal fills the cavity completely, replicating the shape of the pattern with high precision.

6.Cooling & Shakeout

After solidification, the casting is allowed to cool to a controlled temperature. The mold is then broken apart (shakeout process) to release the casting. Remaining sand can be reclaimed and processed for reuse after removing resin residues. The casting is cleaned, and further finishing processes such as grinding, machining, or heat treatment are carried out to meet final specifications.

Applications of No-Bake Resin Sand Casting

1. Automotive Industry

Examples: Engine blocks, exhaust manifolds, brake components, and transmission housings.

Why No-Bake Resin Sand Casting: The process ensures tight dimensional tolerances and smooth surfaces, which are critical for engine and brake components. Its ability to produce both medium-sized and large castings makes it ideal for automotive parts that must withstand heat, stress, and wear while maintaining high performance.

2. Heavy Machinery

Examples: Large housings, machine frames, gearboxes, and bearing supports.

Why No-Bake Resin Sand Casting: Heavy machinery often requires oversized and structurally robust castings. The strong resin-bonded molds can withstand the high pressure of molten metal, allowing the production of large, single-piece castings that eliminate the need for welding or assembly. This improves reliability and reduces weak points in equipment.

3. Energy Sector

Examples: Turbine housings, valve bodies, pipe fittings, and pump casings.

Why No-Bake Resin Sand Casting: Components in the energy industry must perform in high-temperature, high-pressure, and corrosive environments. The excellent surface finish and dimensional stability of this process improve fluid flow efficiency in turbines and pumps, while also extending service life by reducing stress concentrations and machining defects.

4. Mining & Construction Equipment

Examples: Wear-resistant liners, gear housings, shovel arms, brackets, and structural supports.

Why No-Bake Resin Sand Casting: Mining and construction parts are often large, heavy-duty, and exposed to abrasive environments. This process is capable of producing durable, wear-resistant castings with complex geometries, reducing the need for fabrication and ensuring longer service life in tough working conditions.

5. Custom Industrial Components

Examples: Prototypes, low-volume production runs, customized housings, oversized castings, and replacement parts.

Why No-Bake Resin Sand Casting: Its flexibility makes it ideal for custom and specialized castings, especially when permanent tooling is too costly. The ability to quickly produce molds for prototypes or limited production ensures shorter lead times, making it a preferred choice for industrial R&D and tailored solutions.

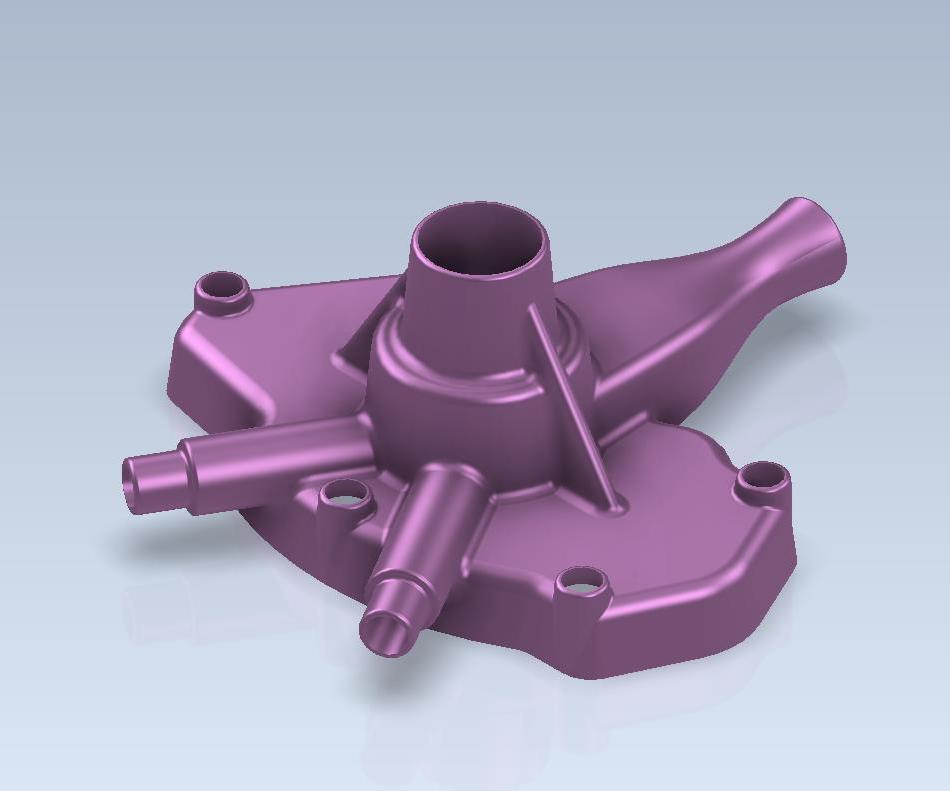

Examples of No-Bake Resin Sand Casting Products

FAQs

Q: What materials can be cast with no-bake resin sand casting?

A: Steel, stainless steel, alloy steel, ductile iron, grey iron, and non-ferrous metals.

Q: What sizes of castings are suitable?

A: From medium-sized precision parts to very large castings weighing several tons.

Q: How does it compare with green sand casting?

A: No-bake resin sand casting provides stronger molds and higher accuracy, while green sand is more economical for mass production.

Q: Is the sand reusable?

A: Yes, but it requires reclamation processes to remove the resin binder.

Q: What industries benefit most?

A: Automotive, heavy equipment, energy, mining, and machinery manufacturing.