Brackets

Grey Iron Brackets are essential structural components used for mounting, supporting, or connecting parts in various mechanical systems. Commonly applied in automotive systems, industrial machinery, agricultural equipment, and construction hardware, these brackets offer excellent rigidity, vibration damping, and machinability. Produced with high-quality grey cast iron (typically EN-GJL-200 or EN-GJL-250), they are designed for strength, dimensional accuracy, and long-term performance under static or low-dynamic loads.

Key Features

High structural strength

Grey iron brackets offer excellent compressive strength (suitable for mounting and load-bearing applications), while maintaining dimensional accuracy.

Superior vibration damping

The graphite flakes in grey cast iron absorb vibrations (reducing noise and fatigue in mechanical assemblies), ideal for engines and rotating equipment.

Cost-effective and stable material

Grey iron is economical for large or complex bracket shapes (especially where tight tolerances are required but high ductility is not essential).

Excellent machinability

Brackets are easy to machine (with minimal tool wear), making it efficient to create mounting holes, threaded features, or mating surfaces.

Corrosion resistance in indoor or coated environments

Grey iron performs well in non-aggressive environments or when surface-treated (painted or powder-coated) for outdoor use.

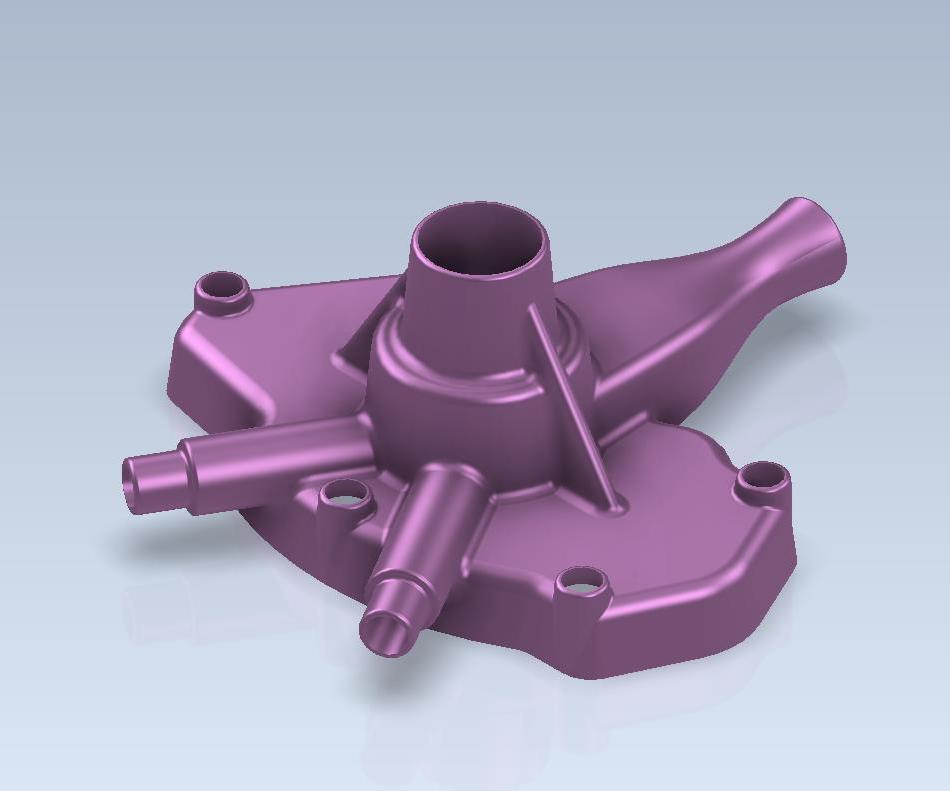

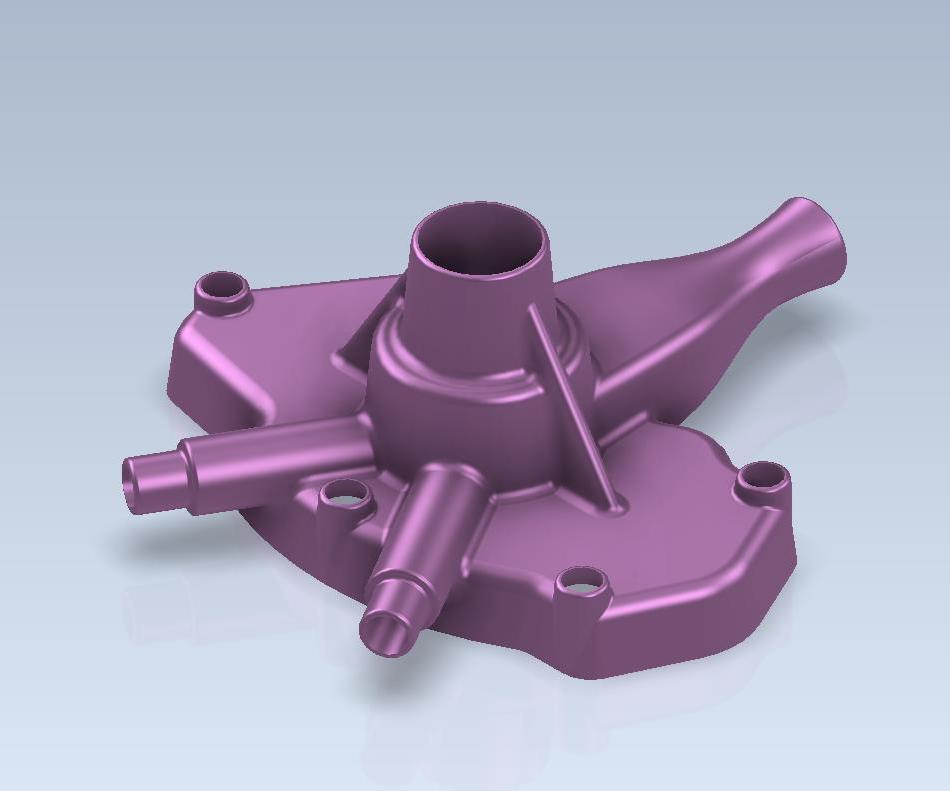

3D models are created based on customer drawings, considering shrinkage and machining allowance.

Patterns are CNC-machined from wood, aluminum, or resin, depending on accuracy and production volume. Wood is used for small batches, aluminum for durability, and resin for complex, high-precision parts.

Green sand molding is used for standard shapes and high-volume production, offering good economy and speed. Resin sand molding is selected for complex geometries or tighter tolerance needs.

Cores are made when internal passages are required. Core shooting machines produce sand cores using cold-box or hot-box technology, which are then precisely placed into the mold before pouring.

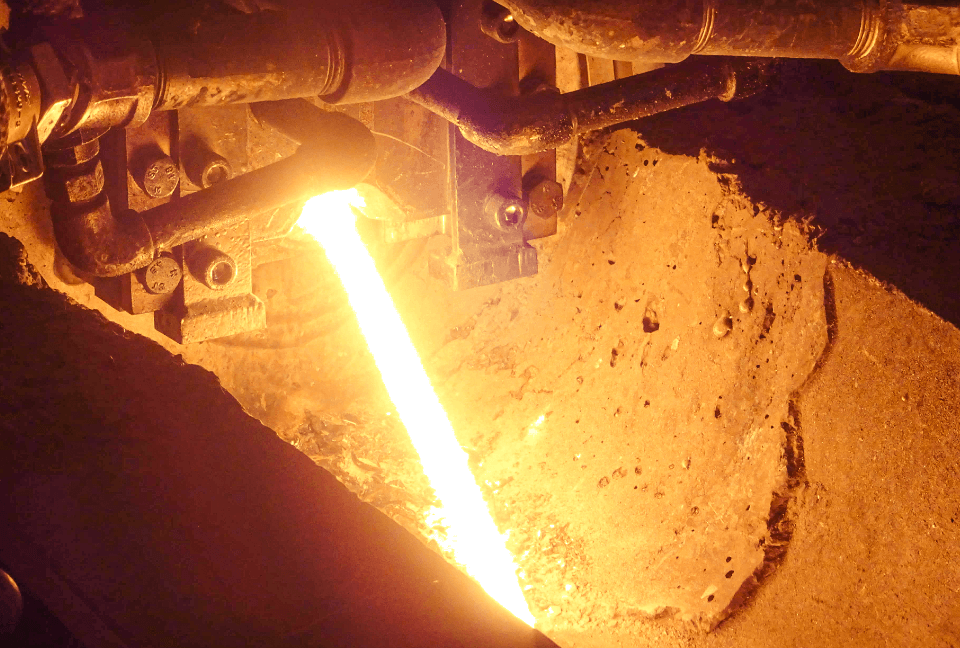

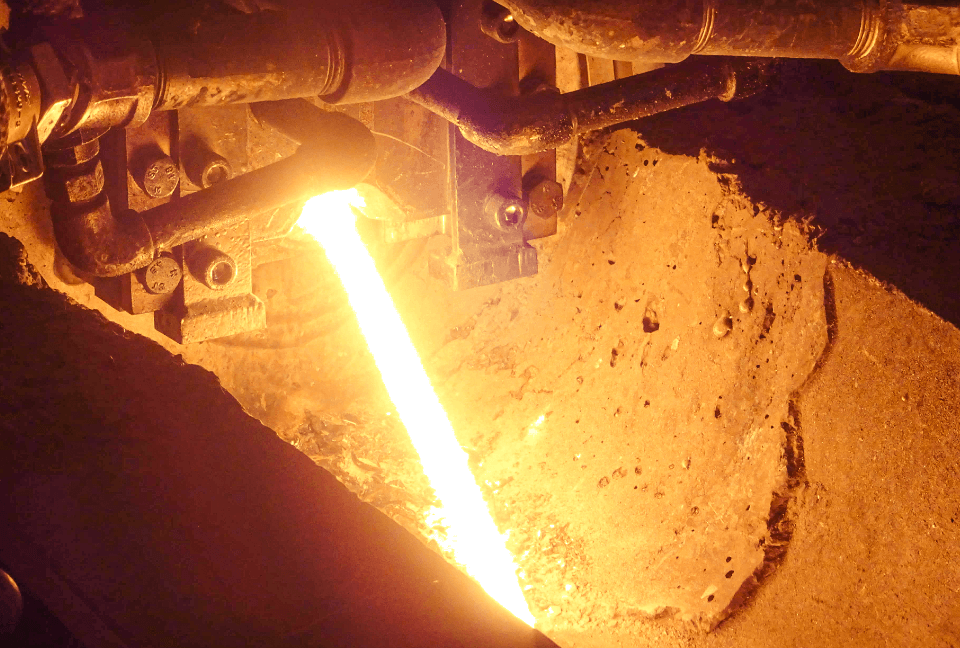

Grey iron is melted in a medium-frequency induction furnace. The raw material mix typically includes pig iron, scrap steel, and recycled castings to ensure stable composition.

Molten iron is poured into the prepared molds at controlled temperatures, usually between 1350°C and 1450°C, to ensure smooth flow, complete filling, and minimal casting defects.

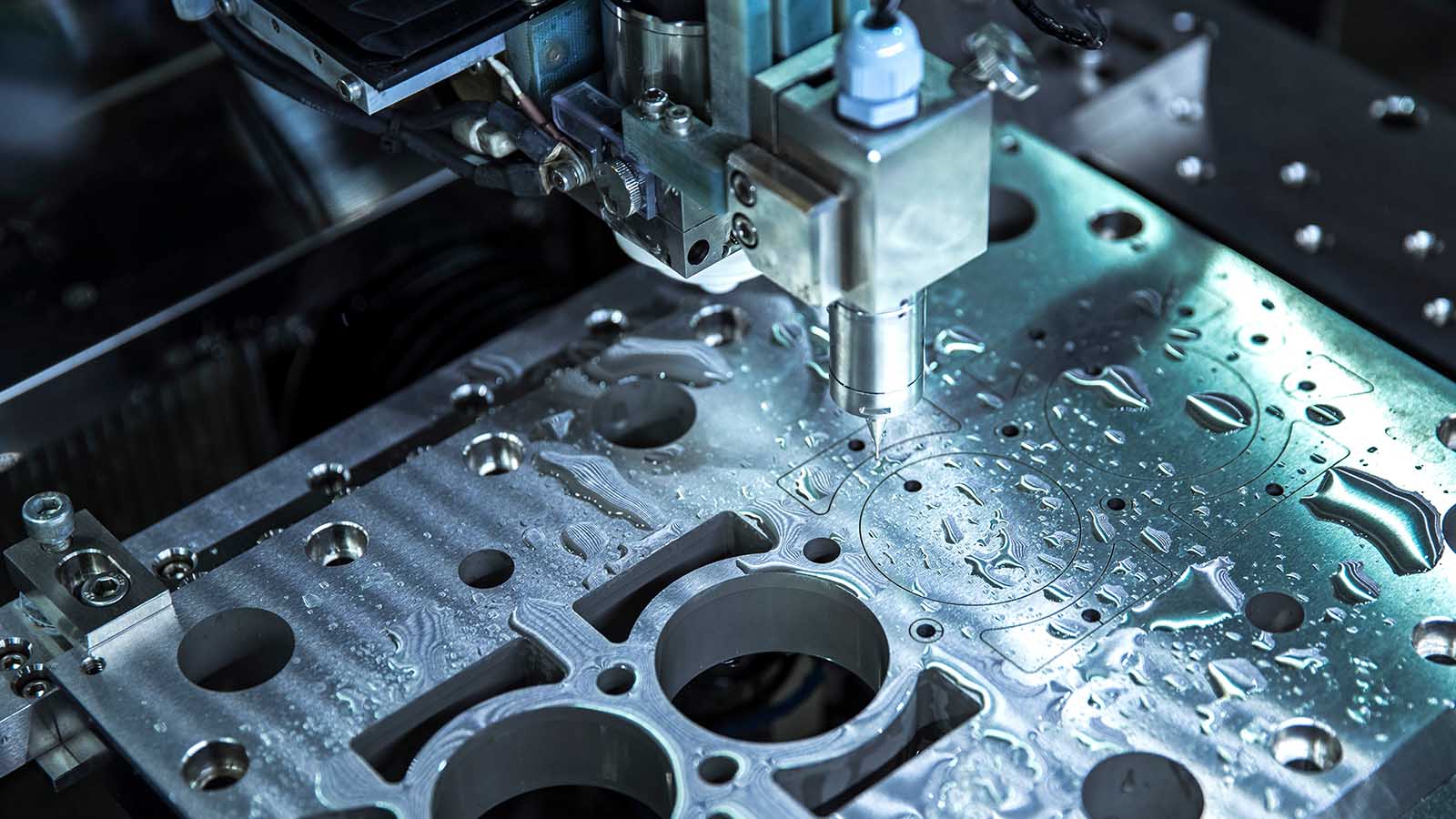

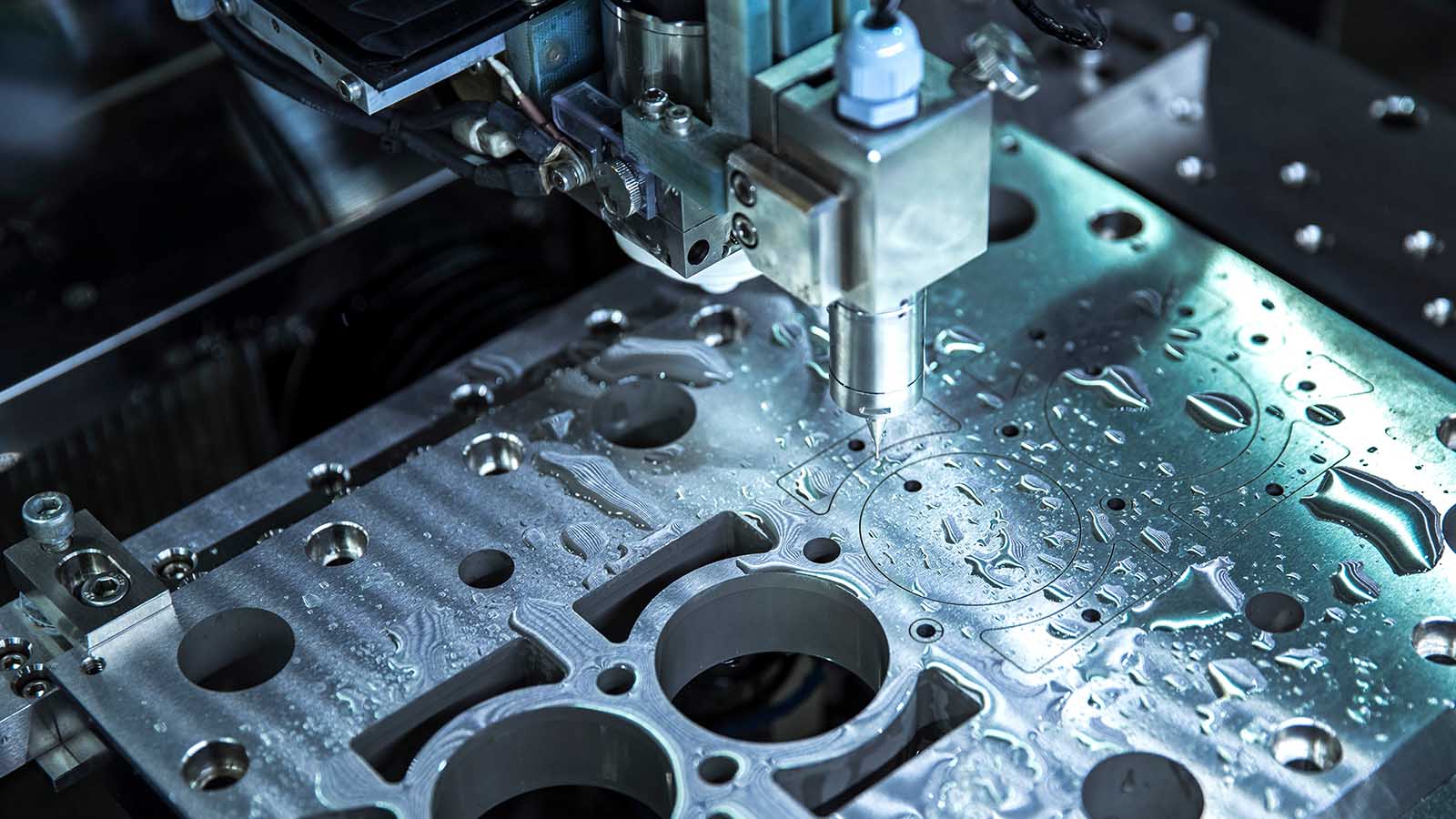

CNC machining is applied to critical surfaces to achieve required tolerances and finishes. This includes milling, turning, and surface grinding as needed.

Holes are drilled and threads are tapped according to drawing specifications. Additional treatments such as deburring or surface coating may also be performed upon request.

Castings are cleaned by shot blasting to remove sand residue, scale, and oxides, revealing the metal surface underneath.

Fettling involves removing gating systems, risers, and any excess material using cutting tools or grinders. Care is taken not to affect dimensional accuracy.

Castings are cooled in the mold under controlled conditions to minimize internal stress and distortion. Cooling time varies depending on part size and wall thickness.

After cooling, molds are broken apart and the castings are removed. The sand is separated and recycled for use in future molds.

3D models are created based on customer drawings, considering shrinkage and machining allowance.

Patterns are CNC-machined from wood, aluminum, or resin, depending on accuracy and production volume. Wood is used for small batches, aluminum for durability, and resin for complex, high-precision parts.

Green sand molding is used for standard shapes and high-volume production, offering good economy and speed. Resin sand molding is selected for complex geometries or tighter tolerance needs.

Cores are made when internal passages are required. Core shooting machines produce sand cores using cold-box or hot-box technology, which are then precisely placed into the mold before pouring.

Grey iron is melted in a medium-frequency induction furnace. The raw material mix typically includes pig iron, scrap steel, and recycled castings to ensure stable composition.

Molten iron is poured into the prepared molds at controlled temperatures, usually between 1350°C and 1450°C, to ensure smooth flow, complete filling, and minimal casting defects.

CNC machining is applied to critical surfaces to achieve required tolerances and finishes. This includes milling, turning, and surface grinding as needed.

Holes are drilled and threads are tapped according to drawing specifications. Additional treatments such as deburring or surface coating may also be performed upon request.

Castings are cleaned by shot blasting to remove sand residue, scale, and oxides, revealing the metal surface underneath.

Fettling involves removing gating systems, risers, and any excess material using cutting tools or grinders. Care is taken not to affect dimensional accuracy.

Castings are cooled in the mold under controlled conditions to minimize internal stress and distortion. Cooling time varies depending on part size and wall thickness.

After cooling, molds are broken apart and the castings are removed. The sand is separated and recycled for use in future molds.

Quality Inspection

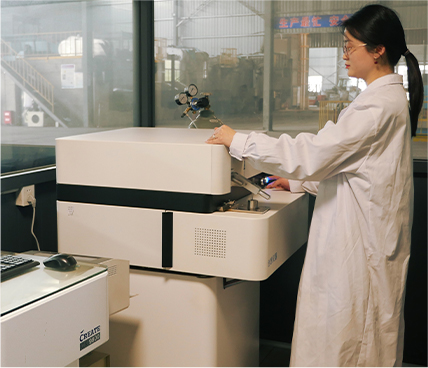

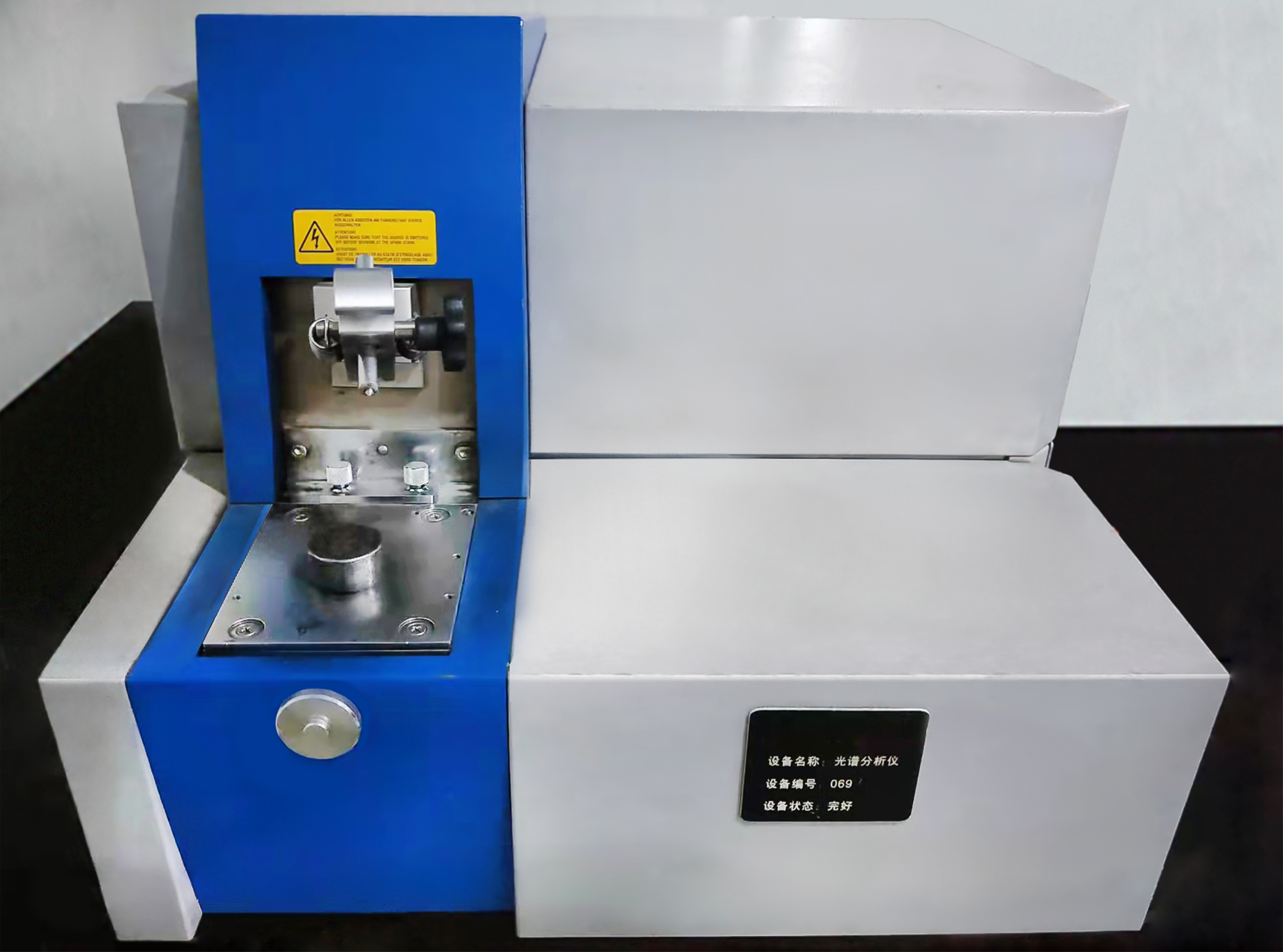

Chemical Composition Testing

Each heat is spectrometer-tested to ensure compliance with required material grades (e.g., EN-GJL-250, ASTM Class 40).

Mechanical Property Testing

Tensile strength and hardness are verified using standard test samples to ensure consistent mechanical performance.

Dimensional Inspection

Critical dimensions (hole spacing, mounting faces, overall geometry) are measured using calipers, gauges, or CMM equipment.

Surface Defect Inspection

Visual checks and magnetic particle inspection are used (if required) to detect cracks, shrinkage, or surface flaws.

Rust Protection Treatment

Before packaging, all castings undergo anti-rust treatment to ensure corrosion resistance during transportation and storage. Common treatments include applying anti-corrosion oil or a water-based rust inhibitor, especially for machined surfaces and critical contact areas.

Secure and Export-Ready Packaging

Each product is carefully packed in fumigation-free wooden crates or reinforced wooden pallets to ensure safety during handling and long-distance shipping. The packaging is compliant with international export standards (ISPM-15) and suitable for sea, air, or land transport.

-

Heavy or large parts are secured with steel straps and foam pads to prevent shifting or collision.

-

Small and medium-sized castings are individually wrapped and separated with protective padding to avoid surface damage.

-

If required, desiccant or shrink film is added inside the packaging to control moisture.

Customized Labeling and Marking

We provide customized labels, barcodes, and product markings based on customer requirements. Typical markings include:

-

Part number and revision code

-

Purchase order number

-

Heat number or batch number for full traceability

-

Customer logo or destination tags (if needed)

Lead Time

Standard lead time is 45 to 55 working days, depending on:

-

Order quantity

-

Whether machining or special testing is required

-

Pattern availability and casting complexity

Urgent delivery requests or phased shipments can be arranged upon agreement.