Shell mold casting

Shell Mold Casting

About Shell Mold Casting

Shell mold casting, also known as shell molding, is a precision casting process that uses a thin-walled shell mold made of fine silica sand coated with thermosetting resin. The sand-resin mixture is applied onto a preheated metal pattern, where the heat cures the resin and forms a hard shell. Multiple layers are added until the shell reaches the required thickness.

This process produces castings with excellent dimensional accuracy, smooth surface finish, and reduced machining requirements. It is commonly used for medium to small-sized parts with intricate geometries, and it works with both ferrous and non-ferrous metals.

Key Advantages

High Precision & Accuracy

Shell mold casting produces parts with tight dimensional tolerances and consistent accuracy. The thin, rigid shell molds replicate the pattern’s details with great fidelity, making it possible to cast complex shapes, fine features, and thin-walled components that are difficult to achieve with traditional sand casting. This precision reduces the need for post-casting adjustments and ensures better fit and function in assembled products.

Smooth Surface Finish

The use of fine-grain silica sand coated with resin creates a mold surface that is smooth and uniform. As a result, the castings have a much better surface finish compared to green sand castings. This minimizes the amount of grinding, polishing, and machining required after casting, lowering finishing costs and improving production efficiency.

Material Versatility

Shell mold casting is compatible with a wide range of metals, including steel, stainless steel, cast iron, ductile iron, aluminum alloys, bronze, and other non-ferrous alloys. This versatility makes it suitable for applications across multiple industries, from automotive to aerospace, where different materials are required to meet performance, weight, and corrosion resistance standards.

Economical for Medium Batches

The process strikes a balance between cost and accuracy, making it especially cost-effective for small to medium-sized castings produced in moderate quantities. Tooling costs are higher than green sand casting but lower than investment casting, offering manufacturers a practical solution for production runs that require precision without excessive investment.

Reduced Defects

The hardened shell molds are strong, erosion-resistant, and thermally stable, allowing for smooth metal flow during pouring. This reduces turbulence and the risk of sand inclusions or surface defects. The result is higher-quality castings with fewer rejections, improving both yield and consistency in production.

1.Metal Pattern Preparation

A heated metal pattern (commonly made from steel or aluminum) is designed and manufactured based on the casting specifications. The pattern surface is polished and sometimes coated with a release agent to ensure smooth surface transfer and easy mold removal. Heating the pattern is essential, as it activates the curing process of the resin-coated sand in the next step.

2.Sand & Resin Coating

Fine silica sand coated with thermosetting resin is evenly applied to the hot metal pattern. As the sand contacts the heated surface, the resin softens and cures, bonding the sand grains together. This creates a thin, hardened layer that replicates the exact details of the pattern surface. The process ensures dimensional accuracy and smooth mold surfaces.

3.Shell Formation

The coating process is repeated multiple times, with each layer building upon the previous one. Layers are applied until the mold reaches the required thickness, typically 5–10 mm depending on the size and weight of the final casting. The multi-layer build-up creates a rigid, durable, and thermally stable shell that can withstand molten metal pouring without deformation.

4.Pattern Removal

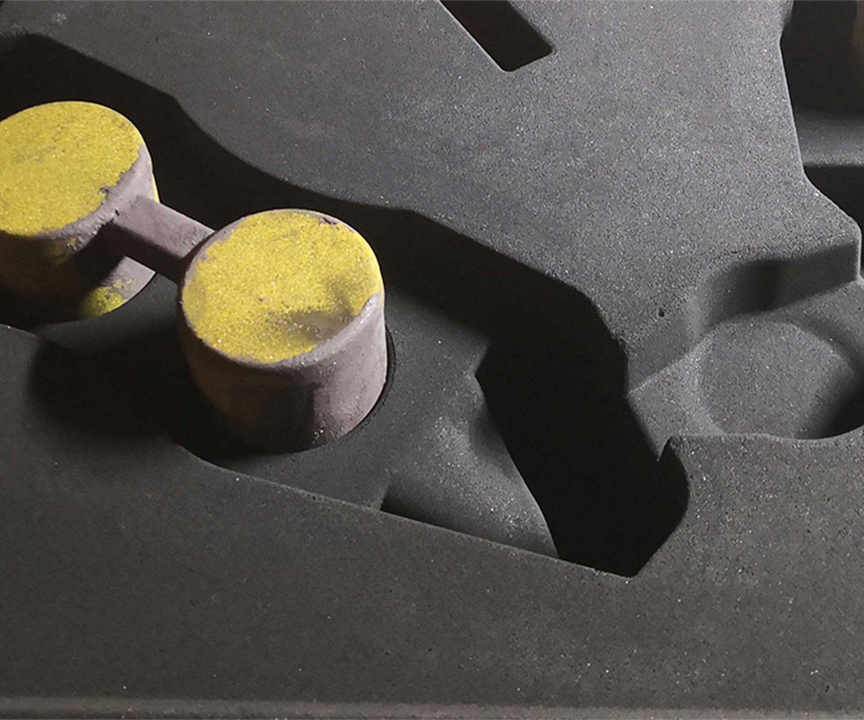

Once the shell mold is hardened, it is carefully removed from the metal pattern. This step requires precision to prevent cracking or damaging the shell. Since the shell is relatively thin but strong, removal ensures the mold retains fine details and dimensional accuracy of the original pattern design.

5.Mold Assembly

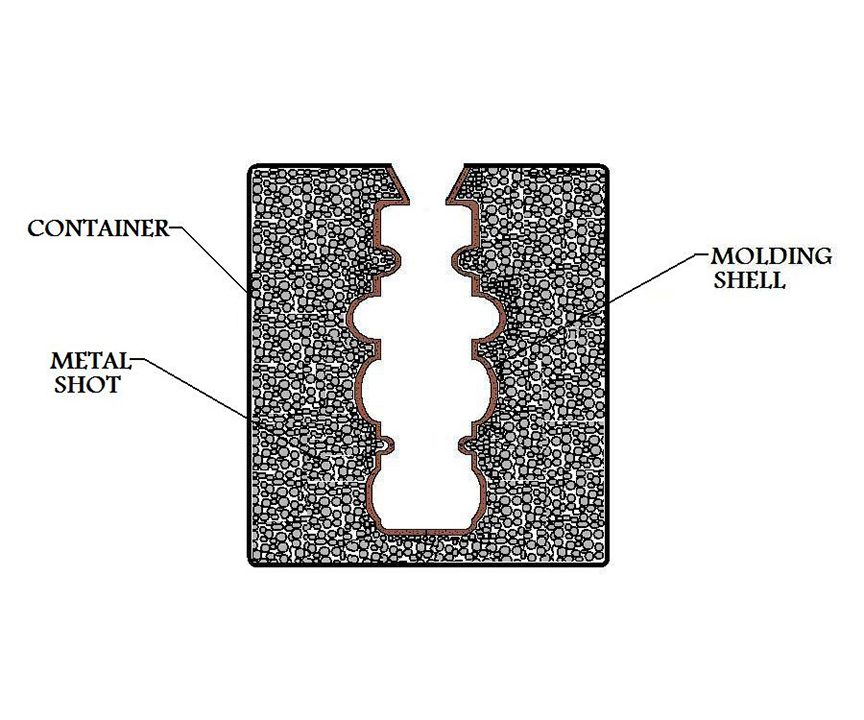

Two shell halves are matched and clamped or glued together to form the complete mold cavity. If the casting requires internal cavities or hollow features, cores made from sand or other materials are inserted at this stage. The assembled mold is then supported with backing materials (like sand or metal shot) to ensure it can withstand the high pressure and weight of molten metal during pouring.

6.Metal Pouring & Cooling

Molten metal is poured into the assembled shell mold through carefully designed gating and riser systems. The strong shell mold allows for smooth metal flow with minimal turbulence, reducing casting defects. After the metal solidifies and cools, the outer shell is broken away or mechanically removed, revealing the finished casting. The casting then undergoes cleaning, trimming, and any necessary machining before final inspection.

Applications

- Automotive Industry

Shell mold casting is widely used in the automotive sector for manufacturing cylinder heads, camshaft housings, intake manifolds, and engine components. The process offers tight tolerances and excellent surface finish, which are essential for components that require precise fits, smooth operation, and durability under high temperature and pressure. It also helps reduce post-machining, saving cost and production time. - Machine Parts

For gear housings, brackets, levers, and pulleys, shell mold casting ensures dimensional accuracy and consistent quality. These parts often have intricate designs and need to withstand heavy loads or wear during operation. The strong shell molds enable the production of such detailed geometries with minimal defects, making them reliable for mechanical and industrial use. - Aerospace Industry

In aerospace, lightweight alloy components with complex shapes, such as structural brackets, housings, and turbine-related parts, are often produced using shell mold casting. The method delivers high precision, fine surface finishes, and reduced machining requirements, which are critical in an industry where both weight reduction and performance reliability are essential. - Energy & Power Sector

Shell mold casting is used for producing turbine blades, valve bodies, pump housings, and other energy system components. These parts often require excellent mechanical strength, smooth surfaces for fluid dynamics, and resistance to heat and pressure. The process ensures consistent quality, making it suitable for both conventional power plants and renewable energy equipment. - General Engineering

In general engineering and custom manufacturing, shell mold casting is ideal for high-precision custom parts, tools, housings, and components where smooth finishes and close dimensional tolerances are required. It is often chosen for prototypes or medium-batch production where accuracy and surface quality can significantly reduce finishing operations.

Examples of Shell Mold Casting

FAQs

Q: What metals are suitable for shell mold casting?

A: Steel, cast iron, stainless steel, aluminum, bronze, and other alloys.

Q: What are the main benefits of shell molding?

A: High precision, excellent surface finish, and reduced machining requirements.

Q: How does it compare with green sand casting?

A: Shell molding offers higher accuracy and surface quality, while green sand is more cost-effective for large, simple castings.

Q: What production scale is best?

A: Ideal for small to medium-sized castings and medium-volume production runs.

Q: Can it handle complex designs?

A: Yes, it can produce intricate geometries and thin-walled components that are difficult with traditional sand casting.