304 stainless steel is one of the most widely used austenitic stainless steels, known for its excellent corrosion resistance, high strength and good weldability. It typically contains 18% chromium and 8% nickel, which is durable, resistant to oxidation and general corrosion. Common applications include kitchen equipment, chemical processing and building structures.

304L stainless steel

304L is a low-carbon version of 304 stainless steel with a maximum carbon content of 0.03%. The reduced carbon content minimizes the risk of carbide precipitation during welding, thereby improving the corrosion resistance of welded parts. It is commonly used in storage tanks, piping systems and heat exchangers.

304H stainless steel

304H is a high-carbon version of 304 stainless steel with a minimum carbon content of 0.04%. The increased carbon improves high-temperature strength and is suitable for boilers, heat exchangers and industrial furnaces.

1. Main characteristics

1.1Excellent corrosion resistance:

304 stainless steel contains more than 18% chromium and more than 8% nickel. These elements form a dense chromium oxide protective film on its surface, which enables it to resist corrosion from most oxidizing acids and alkalis.

In a humid environment, 304 stainless steel can effectively prevent rust, so it is widely used in scenes with high requirements for hygiene and cleanliness.

1.2 Good mechanical properties:

304 stainless steel has high strength and good ductility. It can not only withstand certain mechanical stress, but also realize complex shape processing through cold working.

Its tensile strength σb (MPa) ≥ 515, conditional yield strength σ0.2 (MPa) ≥ 205, elongation δ5 (%) ≥ 40, showing good toughness and plasticity.

1.3 Excellent welding performance:

304 stainless steel is suitable for most welding processes, including arc welding, TIG welding, MIG welding, etc.

It is not easy to produce cracks during welding, the welding quality is stable and reliable, and it can maintain good corrosion resistance after welding.

1.4 High and low temperature resistance:

304 stainless steel performs well in the temperature range of -196℃ to 800℃, and is suitable for industrial environments with extreme temperatures. 304 stainless steel can play its advantages of high and low temperature resistance in equipment such as heat exchangers, boilers, and liquefied gas storage tanks. Diverse surface treatment: 304 stainless steel has a variety of surface treatment methods, including polishing, brushing, electrolytic polishing, etc. It can achieve different decorative effects according to different design requirements while maintaining its corrosion resistance.

1.5 Weak magnetism:

304 stainless steel itself has weak magnetism, but after cold processing such as stretching and stamping, the magnetism will become stronger.

2.Main uses

2.1 Food processing and kitchen equipment:

In the food processing industry, 304 stainless steel is widely used in the production of food processing equipment, storage containers, sinks and kitchen utensils due to its non-toxic and corrosion-resistant properties. For example, breweries, dairy processing plants, condiment factories, etc. often use this material.

2.2 Medical equipment and pharmaceutical industry:

304 stainless steel is easy to clean and has strong antibacterial ability, meeting strict hygiene standards. It is used to manufacture surgical instruments, medical devices and production equipment in the pharmaceutical industry, such as scalpels, operating tables, orthopedic implants, etc.

2.3 Construction and decoration industry:

304 stainless steel has both strength and beauty, and is often used in building curtain walls, railings, floors, interior decoration, elevator panels, stair handrails and various decorative structures.Its rust-proof properties make it an ideal choice for architectural decoration.

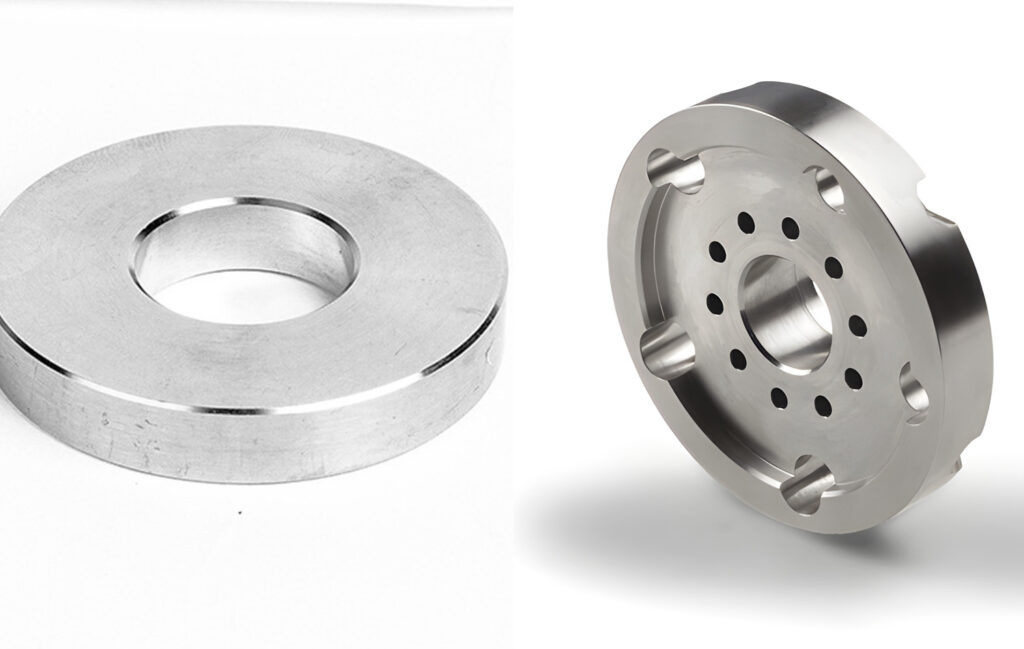

2.4 Industrial equipment:

In the fields of chemical industry and energy, 304 stainless steel is used to produce equipment such as storage tanks, pipes, heat exchangers, etc.Its corrosion resistance and high temperature resistance make it competent for these harsh environments.

2.5 Transportation field:

304 stainless steel is used in car doors, car bodies and auto parts in automobile manufacturing.

In shipbuilding, its good seawater corrosion resistance and high temperature strength make it an ideal material for hulls, cabins, pipes and other parts.

In the field of aerospace, 304 stainless steel is used in engines, turbine blades, gas turbines and other parts.

2.6 Home field:

304 stainless steel is widely used in the manufacture of kitchen utensils, such as pots, bowls, plates, knives and forks, etc.

In terms of bathroom products, such as faucets, bathtubs, toilets, etc., 304 stainless steel is also often used in the manufacture of furniture, such as sofas, beds, chairs, etc.

In summary, 304 stainless steel is widely used in various fields due to its superior properties. Whether it is food processing, medical equipment, architectural decoration, industrial equipment, etc., 304 stainless steel plays an irreplaceable role.