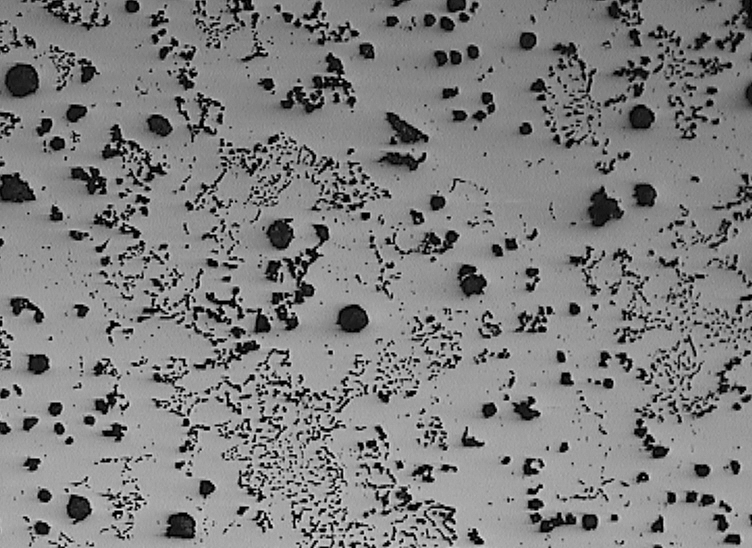

Chunky graphite is one of the common defects of thick and large-section ductile iron castings, which significantly affects the mechanical properties of castings. The chunky graphite phenomenon is currently a topic of great concern in the research and production of thick and large-section ductile iron in the world, but its formation mechanism is still not very clear.

1. Research progress on chunky graphite

1.1 The influence of inoculation

The larger the casting modulus and the lower the cooling rate, the greater the tendency of chunky graphite. Inoculation in the mold increases the number of graphite balls, but also increases the tendency of chunky graphite.

1.2 The influence of microsegregation

Many theories mention that microsegregation is an influencing factor leading to chunky graphite.

1.3 The influence of silicon content and cooling rate

Increased silicon content will lead to a decrease in cooling rate, thereby increasing the risk of chunky graphite. Compared with low silicon content, when the silicon content increases, the cooling rate needs to be increased to avoid chunky graphite.

2. How to avoid chunky graphite

2.1 Reduce or adjust the rare earth content

In most cases, reduce the rare earth content, but rare earth elements are more important for improving nucleation potential, so the lower the better. It is recommended to balance the rare earth Ce content according to the content of trace elements Al, As, Bi, Pb, Sb and Sn.

2.2 Control the amount of Sb and Sn added

Usually 20-50PPM of Sb is added to balance the rare earth. The thick wall part needs to add more than the thin wall. For pearlite-based ductile iron, the addition of Sn can be used to control or avoid chunky graphite.

2.3 Optimize or adjust inoculation

The selection of inoculant is very important. The correct selection of inoculant can help reduce the addition amount and also help reduce the final addition amount. In addition, multi-step inoculation can also help reduce the total inoculation amount. Avoid too low S content (<0.005%), S is a necessary element for nucleation.

3. How to balance rare earth and trace elements

The following control formula is recommended:

RE = 0.5037(Pb+Sb+Bi) + 0.0037. Subsequent observations have found that the formula should also include Ti and As elements, but the correction coefficients of these elements need to be confirmed later.

Therefore, a more accurate formula should be:

RE = 0.5037(Pb+Sb+Bi+Ti+As)+ 0.0037.

4. Future research directions

A deeper understanding of the nucleation and growth mechanism of ductile iron graphite is needed. At present, it is not possible to establish a sufficiently accurate rare earth vs. trace element balance formula, which needs further research. (The main problem is the accurate determination of the rare earth content in the casting, because there is not enough reference material and standards at this stage to ensure the accurate determination of Ce and La in the range of 0.000-0.010%).