The influence of chemical composition on the performance of ductile iron

Chemical composition and metallographic structure

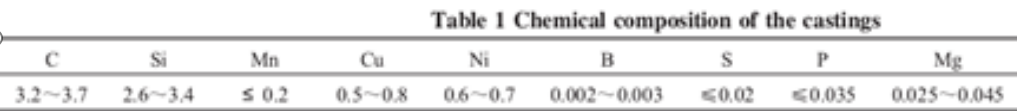

Ductile iron uses Si and B as alloying elements to achieve high strength and high toughness comprehensive mechanical properties of cast ductile iron. Based on this, we designed the main chemical composition of cast QT700-10 as shown in Table 1. Metallographic structure: spheroidizing level 1-2, graphite ball size 6-7, pearlite content 25%~85%.

The influence of chemical composition on mechanical properties

The mechanical properties of metal materials are mainly determined by their matrix structure. To produce cast high-strength and high-elongation ductile iron, it is necessary to first analyze the organizational structure characteristics that this ductile iron should have, and then consider technical solutions and measures. The metallographic structure of ductile iron can be divided into graphite and metal matrix. Its mechanical properties are mainly determined by the metal matrix, but it is also affected by graphite. To obtain high strength and high elongation at the same time, both graphite and matrix structure should have strict requirements.

The performance of the metal matrix can be fully exerted only when the graphite is well spheroidized. Therefore, the production of high-strength and high-elongation ductile iron in the cast state must strictly control the spheroidizing and anti-spheroidizing elements in the molten iron to ensure that the spheroidization rate is above 90%.

Refined graphite balls are very important for high-strength and high-elongation ductile iron. On the one hand, refined graphite balls can improve the roundness and spheroidization rate of graphite; on the other hand, refined graphite balls can reduce the degree of intergranular segregation, prevent the precipitation of brittle phases between grains, and ensure the plasticity and toughness of the material. The technical measures for refining graphite balls are to strengthen inoculation and select high-efficiency inoculants, such as inoculants containing Ba and Bi.

The matrix of ductile iron can be regulated into a variety of structures through alloying and heat treatment to obtain different properties. In order to make the cast ductile iron obtain high strength and high elongation at the same time, it is necessary to seek strengthening and toughening methods without changing the organizational category. Solid solution strengthening and fine grain strengthening can be achieved under cast conditions, and fine grain strengthening improves strength while also improving plasticity. Solid solution strengthening and fine grain strengthening are achieved through alloying. Si, Cu, and Ni are the preferred alloying elements. They all have solid solution strengthening effects, promote primary crystallization graphitization, and have no intergranular segregation. Cu and Ni promote the formation of pearlite and also refine pearlite. Si is an element that promotes the formation of ferrite. Controlling its content can adjust the ratio of pearlite and ferrite in the matrix structure to obtain different strengths and elongations.

According to the above analysis, the matrix structure is selected as a pearlite + ferrite mixed matrix. A certain amount of ferrite guarantees elongation, increases solid solution strengthening, and compensates for the effect of reduced pearlite on strength. Cu and Si are selected as the main alloying elements to verify the role of Ni and B.

Strict production process control

The biggest technical difficulty in producing high-strength and high-elongation ductile iron is that while ensuring strength, a certain ferrite content must be present, especially good graphite spheroidization, small spheroidal diameter, sufficient solid solution strengthening of the matrix structure, grain refinement, few inclusions, and small intergranular segregation. This involves factors such as chemical composition design, low-phosphorus and low-sulfur pig iron raw materials, molten iron smelting and processing technology, and cooling conditions. It is the key to achieving stable production of high-strength and high-elongation cast ductile iron technology.

Test data and result analysis

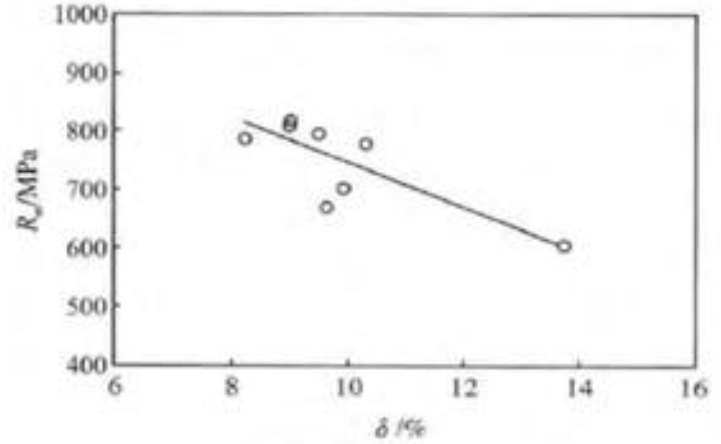

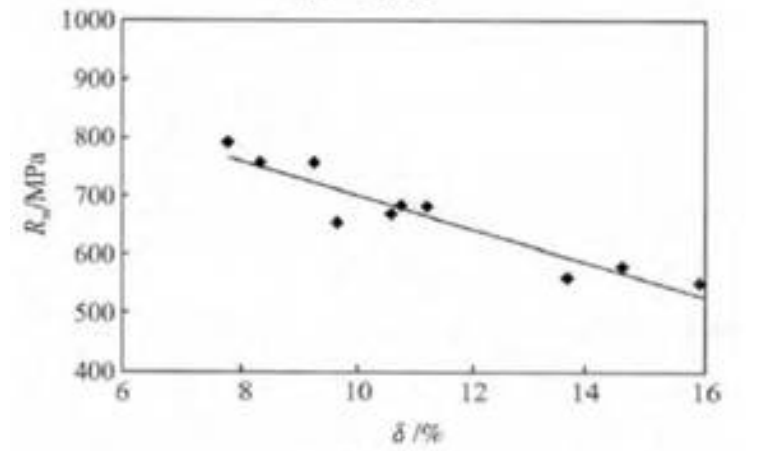

The materials were pig iron and carbon scrap steel, 100 kg coreless medium frequency induction furnace was used for smelting, rare earth magnesium alloy spheroidizer and injection spheroidization were used, ferrosilicon inoculant was used for inoculation (0.1%) and flow inoculation (0.1%), Si, Cu, Ni were added to the spheroidization package, B (0.0025%) was added in the package or with the inoculant, and the standard (GB/T 1348-2009) Y-type test bar was cast. The performance test data was plotted to draw a curve of the relationship between tensile strength and elongation as shown in Figure 2. The mechanical properties of the trial-produced ductile iron are much higher than those of the national standard grades. From the trend line, it can be seen that when the tensile strength reaches 700 MPa, the elongation can reach 10%. The mechanical properties of Si-Cu alloyed ductile iron with B are slightly lower than those of ductile iron without B.

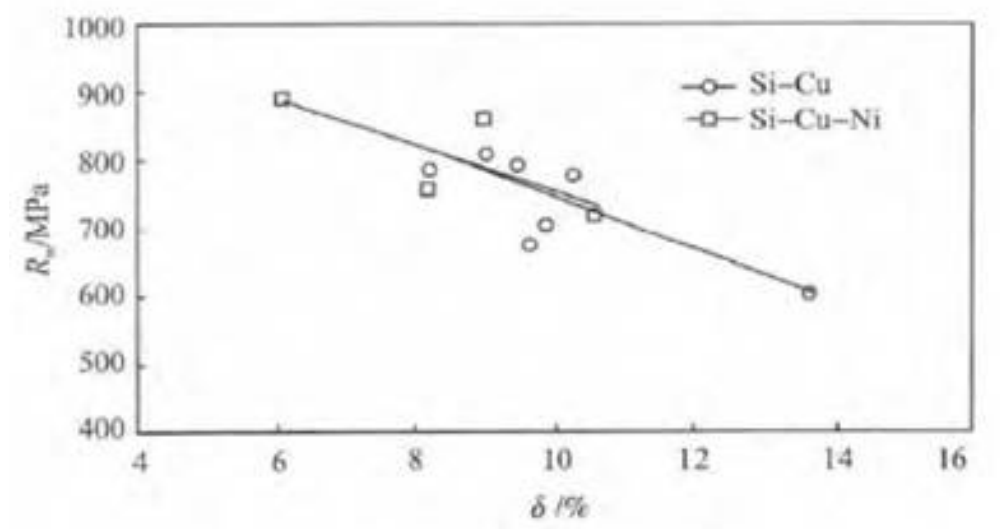

The mechanical properties of Si-Cu alloyed ductile iron with Ni added are compared with those without Ni (Figure 3). Adding Ni can obtain higher strength, and nickel has little effect on elongation. In addition, as the test block thickens, the cooling rate decreases, and the elongation decreases slightly at the same tensile strength.

Without B

Adding B

Figure 2 Si-Cu alloyed cast ductile iron

Figure 3 Comparison of Si-Cu and Si-Cu-Ni alloyed cast ductile iron

Conclusion

Under the experimental conditions, when Si-Cu and Si-Cu-Ni alloys are used to produce cast ductile iron, the elongation can reach 10% when the tensile strength reaches 700 MPa. In actual production, the performance of the casting body and the attached test block is slightly reduced.

The elements and interactions in the molten iron are very sensitive and complex. In addition to controlling the appropriate chemical composition by adding alloying elements, it is also necessary to adopt pure furnace charges, strictly control the smelting, pouring and cooling processes, and strengthen spheroidization and inoculation treatment in order to stably produce high-strength, high-elongation cast ductile iron.