1. Pre-deoxidation

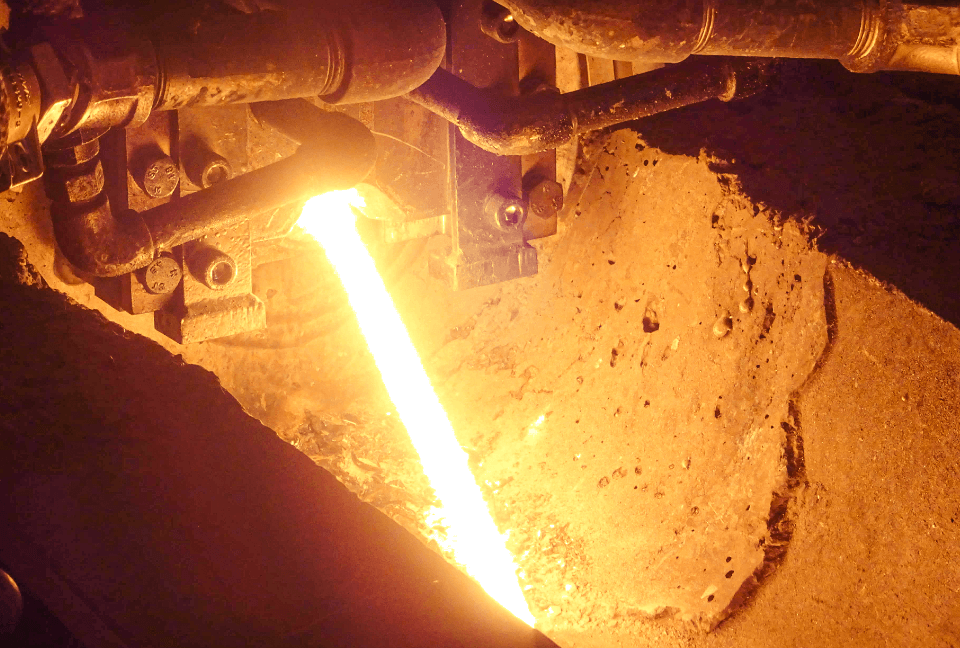

Pre-deoxidation time: When the steel material has been completely melted, but the temperature is not high, generally about ≥1550℃, it is the best time for pre-deoxidation.

Selection of pre-deoxidizer: Select manganese and silicon with better deoxidation effect and higher residual steel as pre-deoxidizer. Electrolytic manganese and crystalline silicon are used for steel with low carbon content, and low-carbon ferromanganese and high-quality ferrosilicon are used for carbon steel.

Amount of pre-deoxidizer added: Add as much as possible on the principle that the residual content of manganese and silicon in the final steel does not exceed the standard to improve the deoxidation effect. In order to form a manganese silicate composite compound that is easy to float, the manganese/silicon ratio must be greater than 1 or higher. Generally, the minimum manganese is 0.5% and silicon is 0.25%.

Sequence of adding pre-deoxidizer: Add manganese first, then silicon. After preheating, the deoxidizer is added to the molten steel by pushing away the slag surface and then covering the molten steel.

Manganese and silicon are the best deoxidizers for molten steel. Although less reactive with oxygen than aluminum, they offer two main advantages. First, they form MnSiO₃ during deoxidation of molten steel. This oxide has a lower melting point than steel and can easily aggregate and float to the surface. Second, steel tolerates relatively high residual manganese and silicon levels. Therefore, adding a slight excess promotes a more effective deoxidation process.

There are two points to keep in mind when using manganese and silicon deoxidizers:

First, add manganese and silicon for deoxidation when the molten steel is at a low temperature, because this is the best period for manganese and silicon deoxidation;

Second, manganese should be added before silicon during deoxidation. Silicon forms flocculent SiO₂, which floats in molten steel. This SiO₂ is difficult to remove directly. Therefore, sufficient MnO must exist before adding silicon. Once SiO₂ forms, it reacts with MnO to produce MnSiO₃. This composite oxide is easier to separate from the molten steel.

Experiments have shown that the inclusion content in steel varies significantly with the order of addition. This is also the reason why we emphasize that the amount of manganese added should be greater than the amount of silicon added, and the manganese-silicon ratio should be at least greater than 1. There is also a saying that when the manganese content in the steel is high, the deoxidation effect of silicon will be better.

The goal of pre-deoxidation is to remove most oxygen using manganese and silicon. These elements form oxides that are easier to eliminate. However, their oxygen affinity is relatively weak. As a result, some oxygen remains in the molten steel. Therefore, manganese-silicon deoxidation is only considered pre-deoxidation.

2. Final deoxidation

Deoxidation time: After the molten steel is left to stand, use an inserted thermocouple to measure the temperature. If the temperature is close to the pouring temperature, final deoxidation can be carried out. If the temperature is too high or too low, it should be adjusted to the pouring temperature range before final deoxidation can be carried out.

Selection of final deoxidizer: Carbon steel uses 0.08–0.1% pure aluminum as the final deoxidizer. Stainless steel first uses 0.15–0.3% silicon-calcium-manganese alloy, then adds about 0.04% pure aluminum for final deoxidation. Alternatively, it may use a silicon-calcium-aluminum-barium composite deoxidizer. The addition amount should be based on the alloy’s aluminum content.

Order and method of adding final deoxidizer: Push away the slag surface and add silicon-calcium-manganese alloy first and then add aluminum immediately. Aluminum has a small specific gravity and calcium-containing alloys are easy to burn. The recovery rate should be considered in the addition method. Insertion or bell jar pressing method can be used to add.

3. Refining treatment

For some steel grades, according to process requirements, refining agents such as rare earth alloys or calcium-containing alloys can be added to the molten steel after final deoxidation, or grain refiners can be added to improve and enhance the performance of the steel. The amount and method of addition are specified in the process documents.

Aluminum has a strong affinity with oxygen and is the strongest deoxidizer for steel, so it is used as the final deoxidizer for steel. The disadvantage of aluminum deoxidation is that the deoxidation product Al2O3 is a cluster oxide. When aluminum is added to the surface of molten steel, it will also form an aluminum oxide film with oxygen in the air. When it is stirred into the molten steel, it is not easy to float out and forms hard and brittle inclusions. Therefore, polished stainless steel parts are taboo to use aluminum as a deoxidizer. The way to overcome this disadvantage is to add silicon, manganese, calcium and other elements while adding aluminum deoxidation. The deoxidation product formed is not a single aluminum oxide, but a multi-component complex oxide, which is easy to separate and float from the molten steel.

Rare earth and calcium-containing alloys have a refining effect on molten steel for the following three reasons:

① They have a strong affinity with oxygen, so they have a deep deoxidation effect on molten steel;

② The melting point of rare earth and its oxide is higher than that of steel. When steel solidifies, it increases the crystal core, thus refining the grains;

③ When there are trace amounts of calcium and rare earth elements in the molten steel, the small amount of oxidized inclusions left by the final deoxidation of the molten steel will be refined and spherical, so the harm to the steel is very small.

However, it should be emphasized that rare earth alloys must be added after the final deoxidation is completed, otherwise too much rare earth oxide will be produced and the molten steel will be polluted. In addition, nano-titanium nitride is a very pure and fine grain refiner. It has a very good effect when added in a few ten-thousandths of an ounce, so it will not have the side effect of polluting the molten steel, but it must be added inside the molten steel to be effective.