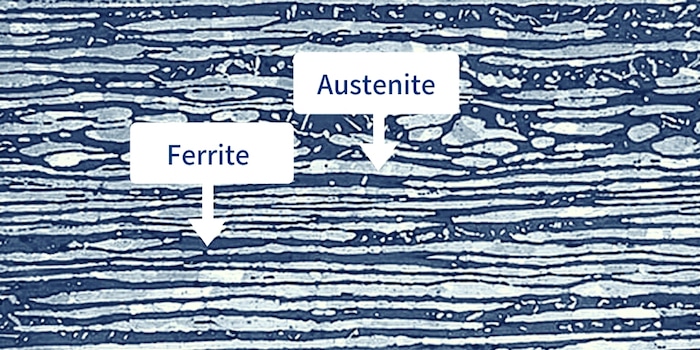

Duplex Stainless Steel (DSS): Structure and Composition

Duplex stainless steel (DSS) refers to stainless steel in which ferrite and austenite each account for approximately 50% of the microstructure, with the lesser phase generally constituting at least 30%. In low carbon conditions, DSS typically contains 18%–28% chromium (Cr) and 3%–10% nickel (Ni). Some types also include alloying elements such as molybdenum (Mo), copper (Cu), niobium (Nb), titanium (Ti), and nitrogen (N).

Material Characteristics

Duplex stainless steel combines the benefits of both austenitic and ferritic stainless steels. Compared to ferritic stainless steel, DSS offers:

- Higher plasticity and toughness

- No room temperature brittleness

- Improved intergranular corrosion resistance and weldability

Meanwhile, it retains characteristics of ferritic stainless steel such as:

- 475 °C brittleness

- High thermal conductivity

- Superplasticity

When compared to austenitic stainless steel, DSS has:

- Higher strength

- Significantly better resistance to intergranular and chloride stress corrosion

- Excellent pitting resistance

- Reduced nickel content, making it a more cost-effective alloy

Development and Applications

Since its development in the United States during the 1940s, DSS has evolved into three generations. A key feature of modern DSS is its high yield strength—ranging from 400–550 MPa—twice that of conventional stainless steel. This makes it a material of choice for reducing structural weight and manufacturing costs.

In highly corrosive environments—such as seawater and chloride-rich conditions—DSS offers superior resistance to:

- Pitting

- Crevice corrosion

- Stress corrosion

- Corrosion fatigue

Its performance is comparable to high-alloy austenitic stainless steel in many cases.

Performance Characteristics

Due to its dual-phase structure and carefully controlled chemical composition and heat treatment, DSS offers the following advantages:

- Stress Corrosion Resistance

Molybdenum-containing DSS performs well under low-stress chloride stress corrosion conditions. While 18-8 austenitic stainless steel tends to crack in neutral chloride solutions above 60 °C, DSS resists such cracking—even in environments containing trace chloride and hydrogen sulfide, such as in heat exchangers and evaporators. - Pitting Corrosion Resistance

DSS has excellent resistance to pitting corrosion. When the pitting resistance equivalent (PRE = Cr% + 3.3×Mo% + 16×N%) is the same, the critical pitting potential of DSS matches that of austenitic stainless steel. Steels with 25% Cr and nitrogen exceed the pitting and crevice corrosion resistance of AISI 316L. - Corrosion Fatigue and Wear Resistance

DSS offers good resistance to corrosion fatigue and wear corrosion, making it suitable for components in power equipment such as pumps and valves. - Mechanical Properties

- High strength and fatigue strength

- Yield strength twice that of 18-8 stainless steel

- Elongation in solid solution state: ~25%

- Toughness (AK, V-notch): >100 J

- Weldability

DSS has excellent weldability and low hot cracking tendency. It generally does not require preheating or post-weld heat treatment and can be welded with dissimilar metals like 18-8 stainless or carbon steel. - Hot Workability

- Low-chromium DSS (18% Cr): Wider hot working temperature range and lower resistance than 18-8 stainless; suitable for rolling directly into steel plates.

- High-chromium DSS (25% Cr): Slightly more difficult to hot work, but can still be processed into plates, tubes, and wires.

- Cold Working

DSS hardens more rapidly than 18-8 stainless steel. Higher initial stress is required for deformation of tubes and plates. - Thermal Properties

- Higher thermal conductivity

- Lower linear expansion coefficient

These make DSS ideal for equipment linings, composite plates, and heat exchanger cores, with better heat transfer efficiency than austenitic stainless steel.

- Brittleness Limitations

Despite its advantages, DSS still exhibits the brittleness associated with high-chromium ferritic stainless steels. It is unsuitable for service above 300 °C. Reducing the Cr content can minimize the formation of harmful brittle phases such as the sigma (σ) phase.