Investment casting, also known as lost-wax casting, is one of the oldest manufacturing techniques, with origins dating back thousands of years. Today, it remains a cornerstone of modern industry, offering unparalleled precision and versatility for producing complex components. From aerospace to medical devices, investment casting plays a crucial role in creating parts that meet exacting standards. This article provides an in-depth overview of the investment casting process, its advantages, challenges, and applications, as well as its future prospects.

Principles

Investment casting involves creating a detailed wax pattern, which serves as a model for the final part. This pattern is coated with a ceramic material to form a mold. Once the mold hardens, the wax is melted and drained away, leaving a cavity that is filled with molten metal. The result is a highly accurate replica of the original pattern.

This process is particularly well-suited for manufacturing components with intricate geometries, fine details, and tight tolerances. The ability to produce near-net-shape parts with minimal machining has made investment casting a go-to method for high-value and critical applications.

The Investment Casting Process

Investment casting consists of several stages, each of which is vital for achieving precision and quality:

1. Pattern Creation

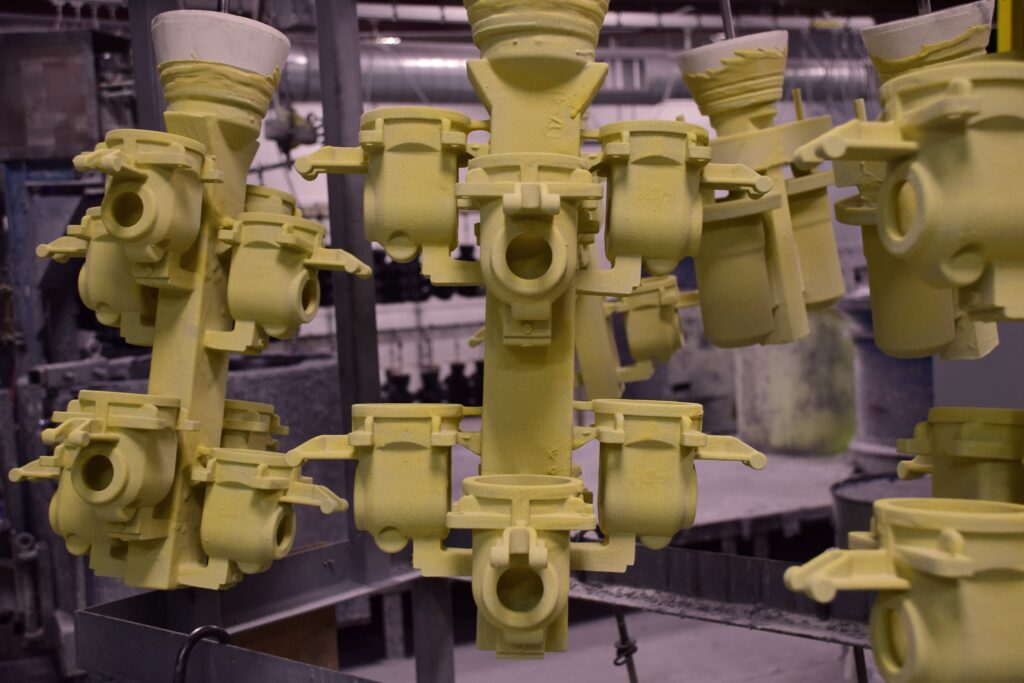

The process begins with the creation of a wax pattern. Patterns can be made using injection molding or 3D printing, depending on the complexity and production volume. In some cases, multiple patterns are assembled into a tree structure to allow for the simultaneous casting of multiple components.

2. Assembly

For high-volume production, multiple wax patterns are attached to a central wax sprue to form a cluster. This assembly simplifies handling and allows for efficient casting.

3. Ceramic Shell Building

The wax assembly is dipped into a slurry of ceramic material and then coated with fine sand. This process is repeated multiple times to build up a thick, durable shell. Each layer is dried before the next is applied to ensure structural integrity.

4. Dewaxing

Once the ceramic shell is complete, the assembly is heated in an autoclave or furnace to melt and remove the wax. This leaves behind a hollow ceramic mold ready for metal casting.

5. Metal Casting

Molten metal is poured into the ceramic mold, filling the cavity left by the wax pattern. The choice of metal depends on the application, with common options including steel, aluminum, titanium, and various superalloys.

6. Cooling and Solidification

The molten metal is allowed to cool and solidify within the ceramic mold. Controlled cooling ensures the desired mechanical properties and minimizes internal stresses.

7. Shell Removal

The ceramic shell is broken away using mechanical or chemical methods, revealing the raw cast part.

8. Finishing

The final stage involves removing any gating, sprues, or excess material. Additional processes like heat treatment, machining, or surface finishing may be performed to meet specific requirements.

Advantages

Investment casting offers a range of benefits that make it a preferred choice for high-precision manufacturing:

- Design Flexibility

The process allows for the production of intricate geometries and complex shapes, including internal cavities and undercuts. - Excellent Surface Finish

Investment casting delivers a smooth surface finish, reducing the need for extensive post-casting machining or polishing. - High Dimensional Accuracy

Tight tolerances can be achieved, ensuring that parts meet exact specifications. - Material Versatility

A wide variety of metals and alloys can be used, making the process adaptable to different applications. - Reduced Material Waste

Near-net-shape casting minimizes material waste, contributing to cost-efficiency and sustainability. - Scalability

Investment casting is suitable for both low-volume and high-volume production, offering flexibility for manufacturers.

Challenges

Despite its advantages, investment casting is not without challenges:

- High Initial Costs

The creation of molds and patterns requires significant upfront investment, making the process less cost-effective for small production runs. - Long Lead Times

The multiple stages involved in investment casting can result in longer production times compared to other methods. - Size Limitations

While ideal for small to medium-sized components, investment casting may not be suitable for very large parts. - Fragile Patterns

Wax patterns are delicate and require careful handling to avoid deformation or damage. - Environmental Concerns

The process generates waste materials, such as ceramic shells and wax residues, which must be properly managed to minimize environmental impact.

Applications

Investment casting is employed in a diverse range of industries due to its precision and adaptability:

1. Aerospace and Defense

The aerospace sector relies heavily on investment casting for components such as turbine blades, engine housings, and structural parts. These parts require high strength, lightweight properties, and exceptional heat resistance.

2. Automotive Industry

In the automotive industry, investment casting is used to manufacture critical components like engine parts, transmission housings, and suspension components.

3. Medical Devices

The process is instrumental in producing medical implants, surgical tools, and prosthetics, where biocompatibility and precision are paramount.

4. Energy Sector

Investment casting is employed in the energy industry for parts like gas turbine components, pump housings, and valve bodies.

5. Art and Jewelry

The ability to produce fine details makes investment casting a popular choice for creating sculptures, ornaments, and intricate jewelry designs.

Innovations and Future Trends

Recent advancements in technology are driving the evolution of investment casting:

1. 3D Printing Integration

Additive manufacturing is revolutionizing pattern creation, enabling faster prototyping and greater design freedom.

2. Advanced Materials

Research into high-performance alloys and composites is expanding the range of materials that can be used in investment casting.

3. Sustainability

Efforts to reduce waste and improve energy efficiency are making the process more environmentally friendly.

4. Automation

The adoption of robotics and automation in shell building and metal pouring is enhancing consistency and reducing labor costs.

Conclusion

Investment casting remains an indispensable manufacturing process, offering precision, versatility, and reliability across a wide range of industries. While it faces certain challenges, ongoing innovations are addressing these issues and paving the way for even broader applications. As technology advances, investment casting will continue to play a vital role in meeting the demands of modern engineering and design.