Introduction

Lost foam casting (LFC) is a modern, highly versatile casting process that has transformed the manufacturing of complex metal components. Since its development in the mid-20th century, it has gained significant traction in industries such as automotive, aerospace, and heavy machinery due to its ability to produce intricate shapes with minimal finishing. This article delves into the principles, processes, advantages, challenges, and applications of lost foam casting, highlighting its importance in modern manufacturing.

Principles of Lost Foam Casting

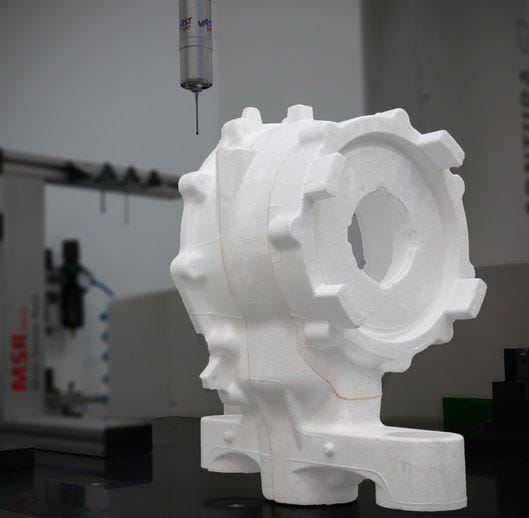

Lost foam casting is a variation of investment casting, leveraging expanded polystyrene (EPS) patterns instead of traditional wax patterns. The core idea is to create a pattern that is coated with refractory material and then embedded in sand. When molten metal is poured into the mold, the EPS pattern vaporizes, leaving behind a cavity that perfectly replicates the pattern’s shape.

This process is especially suitable for creating complex geometries, as the EPS patterns can easily be shaped using molding techniques or additive manufacturing.

The Lost Foam Casting Process

The lost foam casting process consists of several critical stages:

1. Pattern Creation

The first step involves the creation of a pattern using EPS. This material is lightweight, easy to shape, and burns off cleanly during casting. EPS beads are injected into a mold and expanded with heat, forming the desired shape. For intricate designs, patterns can be assembled from multiple parts using adhesives.

2. Pattern Coating

Once the EPS pattern is complete, it is coated with a refractory material such as ceramic or silica. This coating serves multiple purposes:

- It strengthens the pattern, preventing deformation during handling.

- It acts as a barrier to control the sand’s interaction with the molten metal.

- It ensures smooth surfaces and prevents defects like metal penetration.

3. Mold Preparation

The coated pattern is placed in a flask and surrounded by unbonded, fine-grain sand. Vibratory compaction ensures the sand fills every cavity around the pattern, providing stability and precise mold formation.

4. Metal Pouring

Molten metal is poured directly onto the EPS pattern. The high temperature of the metal vaporizes the EPS, and the vapor is absorbed into the surrounding sand. The molten metal then fills the cavity left by the vaporized pattern.

5. Cooling and Solidification

The metal cools and solidifies within the sand mold, forming the final casting. After adequate cooling, the sand is removed, revealing the metal component.

6. Finishing

The final step involves cleaning the casting to remove any residual sand or refractory coating. Additional processes like machining, polishing, or heat treatment may be performed to meet specific tolerances or enhance material properties.

Advantages of Lost Foam Casting

Lost foam casting offers several benefits that make it a preferred method for manufacturing intricate components:

- Complex Geometries

LFC allows for the production of intricate designs that would be challenging or impossible with traditional casting methods. - Reduced Finishing

The high accuracy of the process minimizes the need for post-casting machining and finishing, saving time and costs. - Lightweight Patterns

EPS patterns are easy to handle and transport, simplifying the production process. - High Material Utilization

Near-net-shape casting minimizes material waste, making LFC an eco-friendly option. - Cost Efficiency

For high-volume production, LFC reduces tooling costs and cycle times, offering significant cost savings. - Surface Finish

The refractory coating ensures smooth surfaces, reducing imperfections in the final product.

Challenges of Lost Foam Casting

Despite its numerous advantages, lost foam casting is not without challenges:

- Pattern Fragility

EPS patterns can be fragile and prone to damage during handling, requiring careful transportation and storage. - Long Lead Times for Patterns

Creating precise EPS patterns, especially for complex designs, can be time-consuming and expensive for small production runs. - Limited Materials

Certain metals with high melting points or reactivity may not be suitable for LFC. - Process Control

The vaporization of EPS introduces variability, making process control and quality assurance critical for consistent results. - Environmental Concerns

The burning of EPS releases gases, necessitating proper ventilation and filtration systems to mitigate environmental and health impacts.

Applications of Lost Foam Casting

Lost foam casting is employed in a wide range of industries due to its ability to produce detailed and lightweight components:

1. Automotive Industry

LFC is extensively used in the automotive sector to manufacture engine blocks, cylinder heads, crankshafts, and suspension components. Its ability to create lightweight parts contributes to fuel efficiency and performance.

2. Aerospace Industry

In aerospace, the process is used to produce components with complex geometries, such as turbine blades and housings, where precision and material integrity are critical.

3. Machinery and Heavy Equipment

Industrial equipment manufacturers utilize LFC for making durable and intricate parts like pump housings, gearboxes, and valve bodies.

4. Artistic and Decorative Applications

LFC is also popular in the creation of sculptures, ornaments, and other artistic projects, as it allows for intricate detailing and smooth surfaces.

Innovations and Future Directions

Recent advancements in materials science and additive manufacturing have opened new possibilities for lost foam casting. The integration of 3D printing technology allows for the rapid prototyping of EPS patterns, reducing lead times and enabling the production of highly complex designs.

Additionally, ongoing research into environmentally friendly pattern materials and advanced coatings aims to mitigate the environmental impact and enhance the performance of LFC.

Conclusion

Lost foam casting is a transformative manufacturing process that combines precision, versatility, and cost-effectiveness. While it presents certain challenges, its benefits have cemented its place in industries requiring intricate and high-quality components. As technology continues to evolve, lost foam casting is poised to remain a cornerstone of modern manufacturing, driving innovation and efficiency across various sectors.